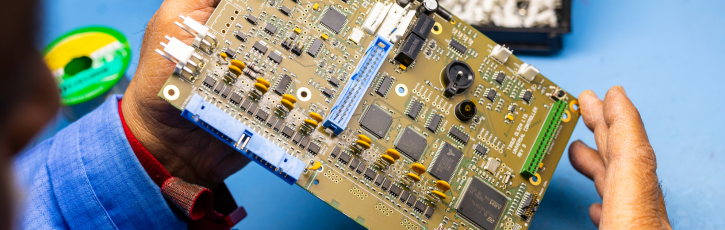

Mixed technology PCB assembly combines surface mount and through-hole components on a single board, a common requirement in industrial, medical, automotive and defence applications. As PCB designs become more compact and complex, this hybrid approach supports performance without sacrificing reliability.

This blog explains what mixed technology assembly is, when it’s used, how they are manufactured and what to look for in a PCB Assembly partner.

Need support? Contact MPE Electronics to discuss your project.

What Is A Mixed Technology Board?

A mixed technology board uses both Surface Mount Technology (SMT) and Through-Hole Technology (THT) on the same printed circuit board. This allows designers to combine the strengths of each approach – SMT for compact, high-speed components and THT for mechanically secure parts such as connectors or large capacitors. Mixed technology PCBs are common in applications where reliability and durability are critical. While this adds complexity to the assembly process, it enables greater design flexibility and supports a wider range of component types within a single build. The result is a robust, high-performance board suited to demanding environments.

When and Why Mixed Technology PCB Assembly is Used

Mixed technology PCB assembly is chosen when a single mounting method doesn’t meet all design or functional requirements. By combining surface mount and through-hole components on the same board, manufacturers can address specific mechanical, thermal and layout challenges.

Why combine SMT and THT?

- Mechanical strength: Through-hole components are ideal for connectors, transformers and large capacitors that may be exposed to stress or vibration. Their leads pass through the board, offering stronger physical anchoring.

- Heat dissipation: Certain THT components handle heat more effectively, making them suitable for power applications.

- Space efficiency: SMT allows for compact layouts and automated high-speed placement, helping reduce assembly time and board size.

- Legacy design: Some components may only be available in through-hole format or must remain in a legacy configuration.

When is mixed technology used?

This approach is common in applications that demand reliability, durability or compact layouts, including:

In these settings, combining SMT and THT provides the flexibility to meet both performance and environmental demands, without compromising on quality or manufacturability.

| See how MPE delivered a mixed technology PCB build for an industrial measurement application in this case study. |

How Are Mixed Technology PCBs Manufactured?

Mixed technology PCB assembly involves multiple stages, each requiring precision to ensure component integrity and reliable board performance. The process must account for both surface mount and through-hole components, which are assembled using different techniques and equipment.

Step 1: SMT placement and reflow

Assembly typically begins with surface mount components. Solder paste is applied to the PCB using a stencil, followed by automated placement of SMT parts. The board is then passed through a reflow oven, where controlled heat melts the solder and secures each component in place.

Step 2: THT insertion

Once SMT components are soldered, through-hole parts are inserted. These components have leads that pass through pre-drilled holes in the board, which will later be soldered from the opposite side.

Step 3: Soldering through-hole components

There are several ways in which THT parts can be soldered:

- Wave soldering is used for boards with many through-hole joints and minimal SMT components on the same side.

- Selective soldering is ideal when SMT components are placed nearby, applying solder only where needed to prevent thermal damage.

- Manual soldering is used for low-volume builds, delicate parts or layouts that restrict access for automated methods.

Step 4: Cleaning, inspection, and testing

After soldering, boards are cleaned to remove flux residues (chemical byproducts from soldering that can attract moisture or cause corrosion). The PCBs are then inspected using automated optical inspection (AOI), X-ray, or manual checks. Functional testing follows to confirm electrical performance.

Strict process control is essential throughout, particularly to avoid damaging SMT components during THT soldering. Learn more about MPE Electronics’ inspection and testing procedures.

SMT vs THT vs Mixed Technology: A Brief Comparison

Each PCB assembly method has its strengths. The table below outlines when surface mount, through-hole or mixed technology is most likely to be suitable, along with typical application areas.

| Approach | Best For | Common In |

| SMT | Small components, high-speed builds | Consumer Electronics |

| THT | Mechanical strength | Aerospace, Industrial, Prototyping |

| Mixed Technology | Complex PCB builds with specific needs | Automotive, Defence, Medical |

Key Benefits and Considerations of Using Mixed Technology PCB Assembly

Mixed technology PCB assembly offers clear advantages when space, reliability and component choice all matter.

Key benefits:

- Design flexibility: Using the best component for each function without being limited to one assembly method.

- Enhanced reliability: Through-hole parts provide secure mounting in high-stress environments.

- Component compatibility: Some parts, like large connectors or legacy components, are only available in THT format.

These advantages make mixed technology a practical choice for high-reliability sectors such as automotive, industrial control and defence.

Context-specific benefits:

In some cases, mixed assembly also supports:

- High-current or high-voltage components: THT parts offer stronger electrical connections for power electronics.

- Ease of rework or servicing: Through-hole components are easier to replace in the field, helpful for long-lifecycle products.

- Prototyping and transitional designs: Useful when integrating older components or allowing for design changes without a full layout redesign.

“Mixed technology builds give our customers more freedom in how they design, but they also place greater demands on process control. That’s where experienced assembly makes the difference.”

- Nicola Evans, Managing Director at MPE Electronics

Considerations:

While mixed technology PCB assembly offers flexibility and reliability, it also introduces certain challenges that must be managed carefully during production:

- Increased complexity: Combining SMT and THT requires more handling and additional steps in the manufacturing process.

- Higher inspection needs: Soldering must be precise, especially near sensitive SMT parts.

- Potential cost impact: More stages can increase production time and overall cost.

What to Look for in a Mixed Technology PCB Assembly Partner

Choosing the right assembly partner is critical when working with mixed technology PCBs. The process is more complex than SMT or THT alone, so experience and capability matter.

Look for a manufacturer with a proven track record in mixed assemblies. They should have dedicated SMT and THT lines, as well as selective soldering equipment to handle boards where both technologies are present on the same side.

IPC-A-610 certified inspectors or equivalent are essential to ensure soldering meets recognised standards. Your potential partner should also be able to advise on layout and manufacturability during early-stage discussions to help avoid delays or rework later.

Finally, full traceability and documentation at every stage supports quality assurance and regulatory compliance, especially important in medical, automotive and defence applications.

An experienced partner will help you balance technical requirements, lead time and cost without compromising build quality.

MPE’s Mixed Technology PCB Assembly Capabilities

With over 30 years of PCB assembly experience, MPE Electronics provides full in-house capability for mixed technology builds, including:

- Prototyping and full production runs

- SMT and THT processes

- Experience with complex builds across industrial, automotive and medical sectors

- UK-based facility, ISO 9001 certified

- Assemblies built to IPC-A-610 standards

Contact our team to request a quote or discuss your project.

Manufacturing Support for Mixed Technology PCB Designs

Mixed technology assembly is often used when a design includes both SMT and through-hole components. It enables compact layouts, secure connections and broad component compatibility, but introduces added complexity during production.

Careful soldering, process control and inspection are essential to maintain quality. MPE Electronics provides full manufacturing support for mixed technology builds, including prototyping and final assembly. If your design is ready for production, our team can help ensure it’s manufactured reliably and to specification.

FAQs About Mixed Technology PCB Assembly

What’s the difference between mixed technology and hybrid PCB?

Mixed technology refers to using both SMT and THT components on the same board. A hybrid PCB usually describes a board made from multiple material types. The terms are sometimes used interchangeably, but they refer to different aspects of design.

Can mixed technology PCBs be prototyped in small batches?

Yes. Mixed technology builds can be produced in small volumes for prototyping or low-runs. Manual soldering or selective soldering is often used at this stage to manage cost and maintain flexibility before scaling.

Does it cost more than SMT-only assembly?

In most cases, yes. Mixed assemblies require more process steps, inspection and handling, which can increase both labour and equipment time. However, the benefits in reliability and design flexibility often outweigh the added cost in critical applications.

What inspection processes are used?

Inspection typically includes Automated Optical Inspection (AOI) for SMT, manual or X-ray checks for THT joints, and functional testing where required. IPC-A-610 standards guide the acceptance criteria to ensure consistent quality across all assemblies.

MPE Electronics is an established and experienced contract electronics manufacturer specialising in PCB assemblies and full box build assembly for a wide range of commercial and industrial businesses.

To find out how MPE Electronics’ PCB manufacturing and assembly services can benefit your business, contact our expert and friendly team on +44 (0)1825 764822 or enquiries@mpe-electronics.co.uk.