THT PCB Assembly Services for Strong, Reliable Connections

High-quality through-hole technology (THT) PCB assembly, delivered as part of a complete UK-based contract electronics manufacturing solution. Our THT assembly services ensure strong, reliable performance in every build.

Contact our team today to explore how we can support your next PCB assembly.

What is Through Hole Technology (THT) Assembly?

Through-hole technology (THT) PCB assembly is a proven method for producing durable, high-performance circuit boards. THT assembly is particularly valuable in applications where:

Mechanical strength is a key requirement

Thermal stability ensures long-term performance

Component reliability is critical under demanding conditions

Applications of THT PCB Assembly

MPE Electronics provides fully managed THT PCB assembly as part of a complete UK-based contract electronics manufacturing solution. Our services support critical sectors including:

Industrial automation and heavy machinery

Power electronics and control systems

Prototyping, product testing and development environments

THT vs SMT: What’s the Difference?

Through-hole technology (THT) components have leads that are inserted into holes drilled in the PCB, offering stronger mechanical bonds.

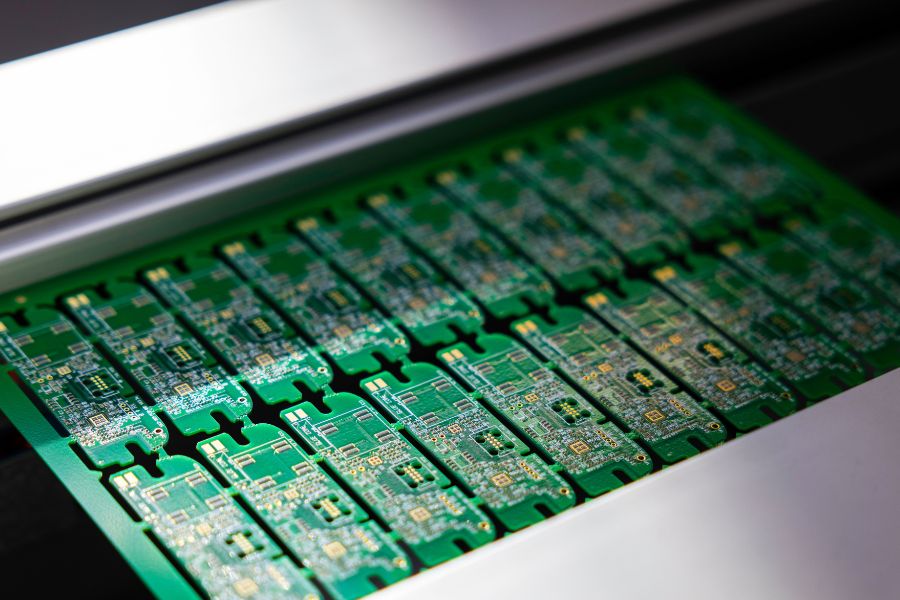

Surface mount technology (SMT) components are mounted directly to the board surface, which is often preferred for compact or high-volume builds. Many assemblies combine both techniques, depending on performance needs.

Integrating THT and SMT in Hybrid PCB Assembly

Through-hole technology (THT) assembly can be integrated into hybrid PCBs, also known as ‘mixed technology’ PCB builds, alongside surface mount technology (SMT). This SMT THT assembly approach allows our customers to benefit from:

Compact board layouts achieved via SMT

Mechanically robust connections offered by THT

Seamless integration of large, heavy or high-power components such as:

Connectors

Relays

Power transistors

THT assembly is particularly suited to boards exposed to vibration, impact or thermal cycling, as well as prototyping stages where components may need to be replaced or tested.

Access Control Case Study: Reliable PCB Assembly in Practice

Our access control case study highlights how well-executed PCB assembly supports long-term product reliability in security-focused applications. Explore the full case study to see how consistent build quality contributes to scalable outcomes.

Benefits of Through Hole (THT) Assembly

While SMT has become standard for high-volume production and compact devices, THT PCB assembly offers distinct advantages in specific scenarios. These include:

Greater mechanical stability for components subject to stress, making it ideal for transport, industrial machinery and field-deployed equipment

Easier modification and replacement of components during prototyping or low-volume production

Compatibility with larger or legacy components not suited to SMT

Improved reliability for power-intensive or mission-critical systems

Enhanced inspection and manual testing capability during the build process

For further insights, see our guide to through-hole assembly.

Our Full THT Assembly Capabilities

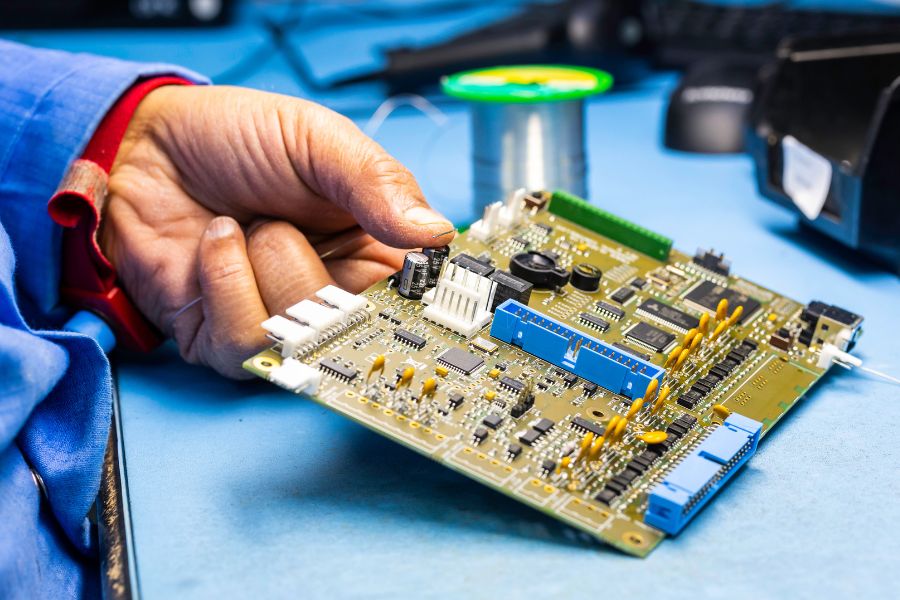

MPE Electronics follows a structured THT assembly process that balances automation with hands-on expertise. Each project is assessed and the appropriate techniques are selected from the following stages:

1. Component insertion using manual placement tools

2. Wave or hand soldering, depending on board complexity and component layout

3. Inspection and testing including in-circuit test (ICT), functional test and visual inspection

4. Cleaning and protection using appropriate solvents and conformal coatings as needed

5. Final quality assurance to confirm performance against specification

For a closer look at standard PCB assembly lead times, see this article.

Soldering Techniques for High-Reliability THT PCB Assembly

Soldering is critical to the quality and reliability of any PCB assembly. At MPE, our THT assembly process applies the most suited method depending on your component mix, board layout and functional requirements.

Wave Soldering for reliable joints

When your assembly includes conventional through-hole mounted components, you benefit from consistent, high-quality joints through automated wave soldering. This process solders all component leads to the board within seconds, producing mechanically and electrically secure joints across the assembly.

Hand Soldering for Precision

Where components cannot be wave soldered due to complexity or layout, our engineers perform precision hand soldering. This process requires exceptional control and craftsmanship. Using carefully selected tip sizes, our engineers form joints that meet the exact mechanical and electrical specifications of the build.

Partnering with MPE Electronics means you receive expert guidance on the most suitable soldering techniques for your assembly.

A Trusted Partner in Contract Electronics Manufacturing

With over 30 years of experience, MPE Electronics supports product designers and sourcing managers looking for a long-term assembly partner. Our THT PCB assembly services are part of a broader manufacturing capability that includes:

Full PCB prototyping, cable assembly and PCB testing

IPC-A-610-certified staff with specific training in THT techniques and standards

ISO 9001 accredited processes supporting traceability and consistency

Modern facilities equipped with dedicated wave soldering equipment and inspection tools

Long-standing client relationships built on quality, reliability and transparent communication

If you’re reviewing potential suppliers, our checklist for choosing an electronics manufacturing partner may be a helpful starting point.

Supporting Services That Underpin Quality Assembly

New Product Introduction (NPI)

Every new project goes through our structured New Product Introduction process. This ensures potential issues are identified and resolved before production begins, keeping your delivery on track and your assembly build process smooth.

End-of-Life Notifications and Component Continuity

We understand how essential component continuity is in contract manufacturing. MPE has robust systems in place to manage End of Life (EOL) and Product Discontinuance Notices (PDNs).

Once notified, our team:

Reviews the impact of the notice on your assembly

Advises on Last Time Buy (LTB) opportunities

Explores and validates alternative parts

Requests and assesses component samples if required

Our strong relationships with approved suppliers ensure we receive EOL updates early and respond proactively to protect your product lifecycle.

Need a Reliable THT Assembly Partner?

Contact us to explore how our THT assembly services fit within your wider manufacturing strategy.

Frequently Asked Questions

Does MPE offer hybrid SMT and THT PCB assembly?

Yes. Our team regularly works on hybrid SMT THT assembly projects where surface mount and through-hole components are used together. This approach provides flexibility in design and enables integration of a wider range of components.

Is through-hole assembly suitable for prototyping?

Through-hole is ideal for prototyping due to the ease of modifying or replacing components. It also provides a more accessible structure for testing and development.

Which industries benefit most from THT PCB assembly?

THT PCB assembly is commonly used in defence, medical, industrial and automotive sectors where operational reliability and long-term durability are critical.

How does MPE ensure quality in THT builds?

We follow a strict quality assurance process including trained personnel, automated and manual inspection methods, documented test procedures and traceable records. All work is carried out in line with IPC-A-610 standards and ISO 9001 quality management system.

Surface Mount Technology