How MPE Scaled from PCB Assembly to Full Box Build for Motorsport Vehicles Display Units

Case Study: How MPE Scaled from PCB Assembly to Full Box Build for Motorsport Vehicles Display Units

The Brief

An existing MPE Electronics customer approached the team with a new and technically demanding product. The project involved full box build for display units used in motorsport vehicles. These units are used in a high-pressure environment where precision and reliability are essential.

While MPE had previously delivered PCB assembly work for the client, this new work required a complete transition to a full box build assembly solution. It was a significant step, not only in terms of scale but also in process and quality assurance. The client needed a manufacturer that could meet exacting quality requirements, accommodate their preferred production method and remain responsive throughout.

The Opportunity

This was not a typical electronics assembly order. The product introduced several requirements, including handling of chemical compounds, installation of new extraction systems and adaptation of a workspace layout to support the client’s workflow. The assembly process had to run smoothly, with accurate control at every stage.

All processes had to remain compliant with MPE’s ISO 9001:2015 certification and Quality Policy, which underpin every project delivered by our team.

MPE Electronics’ Approach

Paul Owen, Production Director at MPE Electronics:

“We’re always ready to adapt if it means delivering the best outcome for the client. This wasn’t a case of fitting the work into our normal processes. We had to set up a dedicated area, introduce new equipment and work closely with the customer to make sure everything aligned with their expectations.”

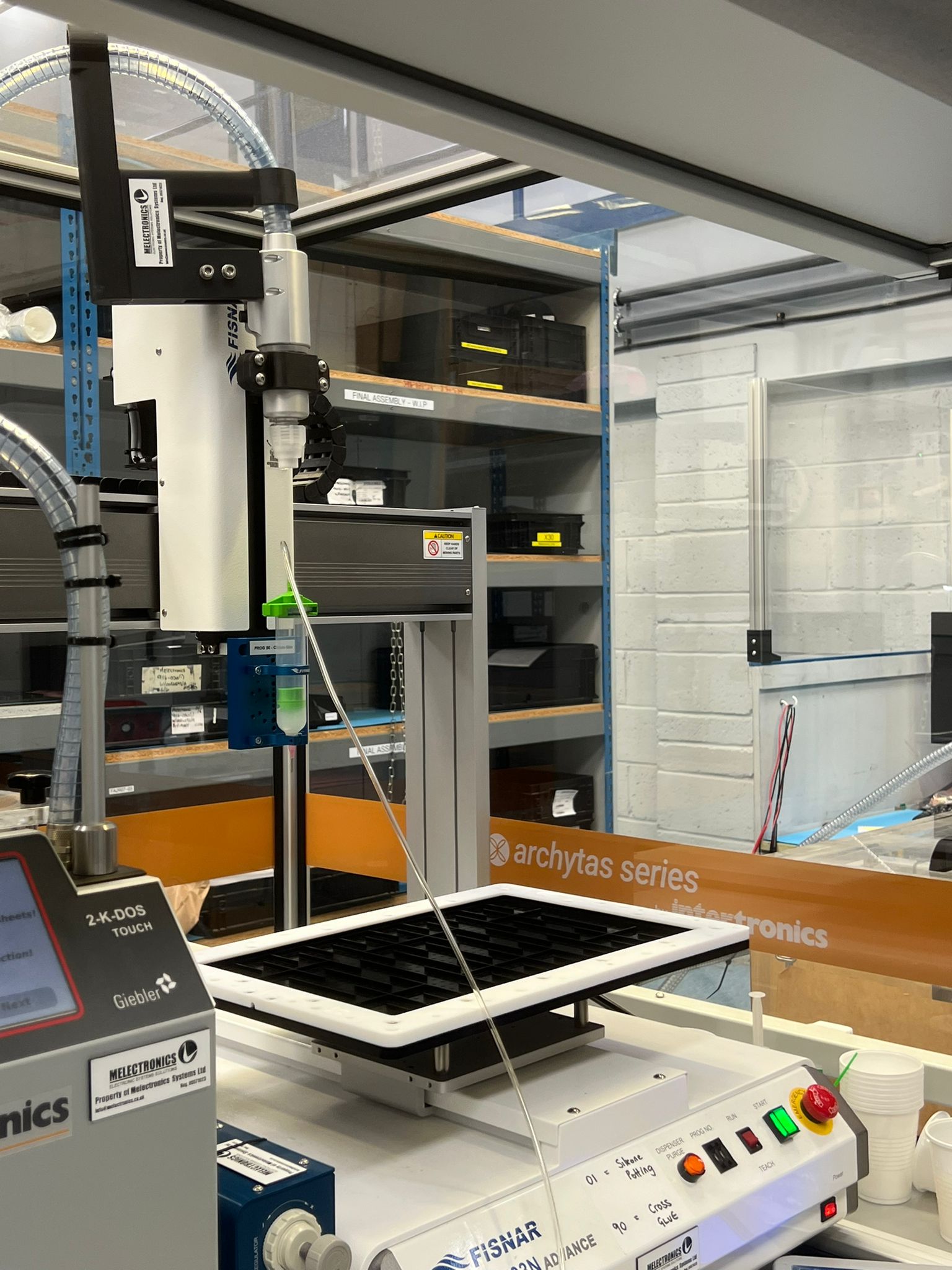

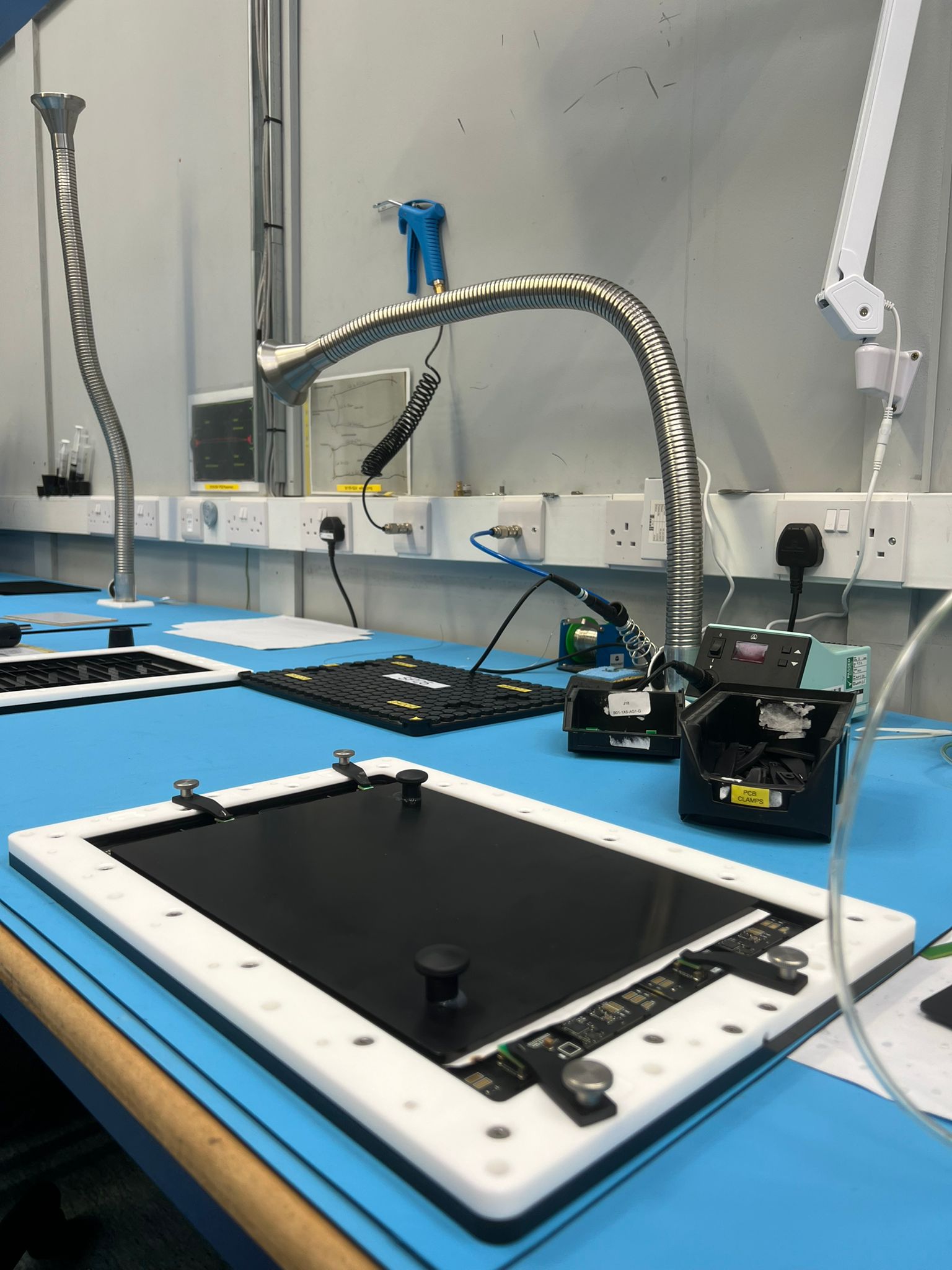

The set-up phase included a three-week training programme provided by the client onsite at MPE’s manufacturing facility., as well as the installation of robotic potting equipment to improve measurement precision and minimise error.

To support safe handling of the materials used in this project, MPE installed local extraction units within the dedicated production area, in order to remove the fumes released during potting, which involves applying encapsulating compounds to protect sensitive electronics. Unlike basic ducted systems, the units selected for this build use advanced filtration and capture technology to extract chemical vapours directly at source. This protects staff, maintains air quality within the workspace and ensures compliance with health and safety standards during continuous production.

Working in close partnership, the client supplied tooling and materials, while MPE delivered the production capability, internal coordination and process control to scale the build effectively. While similar assemblies had previously involved manual potting, this project required robotic application to ensure consistent coverage and more accurate compound measurement. Introducing this technology eliminated variability and helped maintain quality across every unit.

Every step was documented and reviewed to support traceability and quality control.

Project Outcome

The motorsport display unit work highlights MPE’s ability to deliver a full box build solution for a complex and high-profile application. The team adapted the workspace, introduced new equipment and followed a tailored process shaped by close collaboration with the client.

Key outcomes:

A production area configured and operational within weeks

Robotic systems introduced for precision and consistency

Staff trained and equipped to manage the complete build

A final product that met the client’s technical and visual expectations

By working within the framework of ISO 9001:2015, MPE maintained process control, clear communication and accurate record-keeping throughout. The approach helped build trust and ensured the project ran smoothly from initial setup to delivery.

Paul Carter, Sales Director at MPE Electronics:

“We’d built a good relationship with this customer through PCB work. When they brought us something more complex, we were glad to take on the challenge. Our team is experienced and agile, so we knew that by working closely with the client, we were well positioned to shape the set-up around their process and make sure everything ran smoothly.”

Related Case Studies

Explore more examples of how MPE delivers precision PCB assembly:

Full Box Build Wet Tag Assembly Line

We’re here to help

If you’re looking for a PCB supplier, ready and prepared to adapt to your specific or changing needs, please contact us at