Box build assembly is a common process in electronics manufacturing and it is critical that it is carried out to a high standard.

Each box build assembly is product specific and the process is often complicated, requiring specialist skills, procedures and technology. The calibre of the process is integral to product quality and the efficiency of the manufacturing process, which have a direct bearing on time to market and profit margins.

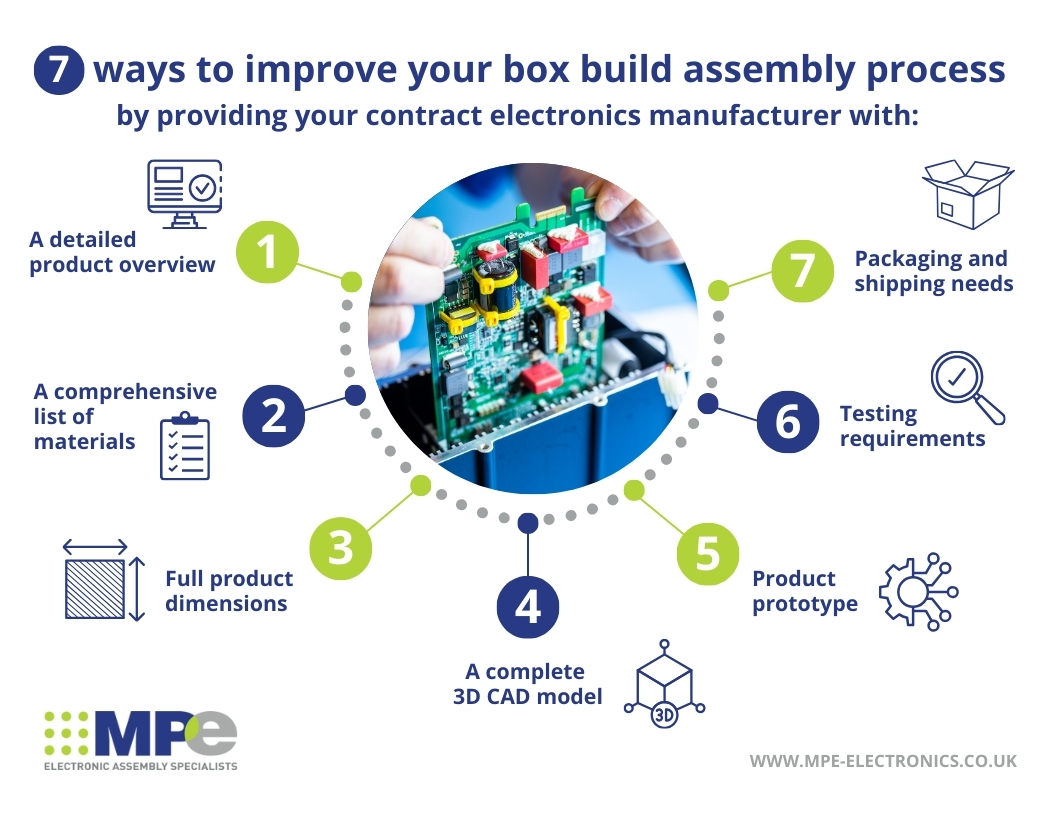

We have put together this short guide to how you can improve your box build assembly.

How to improve your box build assembly process

By providing your contract electronics manufacturer with the following information, you can help make the box build assembly process quicker and more efficient, and help improve the quality of the service and your product.

- A detailed product overview It is vital that the right box is used for your application. By providing a full product overview and information on the conditions in which the product will be used in, you will help make sure that the most suitable box is used in your box build assembly process, and that your product performance expectations are fully realised.

- A comprehensive list of materials This should include the materials to be supplied by you and those you need to be supplied by your electronics manufacturing partner. Attention to detail here, and the provision of as much detail as possible (item numbers, part descriptions, quantities, part numbers, etc.), will help improve the efficiency of the box build assembly process, including in relation to cost and timescale.

- Full product dimensions These details, including information on size and weight, will help your electronics manufacturing services supplier in the design and management of the box build assembly process, including in relation to requirements relating to storage, transportation, packaging and delivery. As a rule MPE Electronics does not require this information for box build assembly projects.

- A complete 3D CAD model This and the visualisation that it provides for the supplier of the box build assembly is hugely important. This data is a key tool in the box build assembly process, including in terms of providing instructions to make it more efficient. Critically, the more complex the design, the higher the costs, so if you can, keep the design as simple as possible. Again, MPE Electronics does not require this information for box build assembly work.

- Product prototype The availability of a product prototype can help your contract electronics manufacturer significantly improve the box build assembly process, in particular if there is a shortage of other information, and ensure the creation of an optimal enclosure. This is especially important with regard to new product introduction and the right partner should be able to develop prototypes if required. Providing a product prototype is optional for MPE Electronics’ box build assembly customers.

- Testing requirements The more information that a contract electronics manufacturer has about what testing is needed, the smoother and quicker the box build assembly will be. The right partner will also be able to fill in testing gaps, including in relation to safety, if required.

- Packaging and shipping needs The supply of detailed information on packaging and shipping is critical to planning. It will help your contract electronics manufacturer design the box build assembly process so that it is as efficient as possible and that lead times are as short as possible.

Box build assembly and the role of your electronics manufacturer

Aside from making sure that you provide all the key information relevant to the box build assembly process, another key factor vital to achieving the manufacturing efficiency and product quality you need is to choose the right electronics manufacturing partner.

When it comes to box build assembly and product manufacturing, the right PCB assembly specialist will ensure that you benefit from advantages such as a simplified supply chain, manufacturing cost-efficiency, full component traceability, comprehensive product management capability and expert pre-process advice and after-sales support.

This standard of service, combined with a proactive and well-organised approach, will help optimise your manufacturing process, your product quality and your time to market.

To find out how MPE Electronics’ PCB manufacturing and assembly services can benefit your business, contact us on +44 (0)1825 764822 or enquiries@mpe-electronics.co.uk.