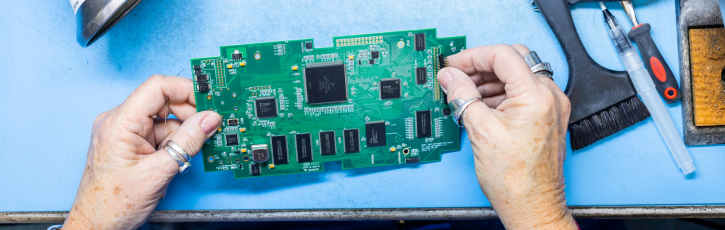

Electronic packaging is a fundamental aspect of the PCB assembly industry, encompassing the technologies and processes involved in safeguarding electronic components. Each electronic packaging type serves vital functions, such as mechanical support, thermal management and ensuring electrical connectivity. This blog will delve into various forms of electronic packaging, examining their applications and significance. By understanding these packaging types, manufacturers and engineers alike can enhance device performance, protect sensitive components and facilitate seamless integration within electronic systems.

What do we mean by electronic packaging?

Electronic packaging refers to the technology involved in enclosing and protecting electronic components and assemblies, such as integrated circuits (ICs), printed circuit boards (PCBs) and various electronic devices. Each type of electronic packaging serves specific functions, including mechanical support, thermal management and providing connectivity among components.

In essence, electronic packaging is a critical aspect of electronic design and manufacturing, ensuring that components function correctly, remain protected and interact seamlessly within the device.

The different types of electronic packaging by application

Electronic packaging can take a range of forms, including:

Integrated Circuit Packages

Integrated Circuit (IC) Packages are used in just about every electronic device, including smartphones, computers and consumer products, where semiconductor chips are encapsulated, whereby they are surrounded and protected by a solid material, to protect and facilitate electrical connections.

What are the different types of IC Packages?

The most common types of IC packages include:

Dual or Double In-line Package

A Dual or Double In-line Package (DIP) is a rectangular package with two parallel rows of pins suitable for through-hole mounting. They are widely used in prototyping owing to ease of insertion. Since the 2000s, Dual In-line Packages have largely been replaced by Surface Mount Devices (SMDs) owing to the advantages they offer in terms of space efficiency, automated assembly and higher performance.

Surface-Mount Device Packages

Surface-Mount Device (SMD) Packages are designed for mounting directly onto the surface of PCBs without through-hole connections. Common types include:

- Small Outline Integrated Circuit (SOIC) – a thinner version of DIPs with shorter leads.

- Thin Small Outline Package (TSOP) – an even thinner version of SOIC packages, used for memory chips.

- Quad Flat Package (QFP) – features pins on all four sides, commonly used in microcontrollers and Field-Programmable Gate Array (FPGA), a type of semiconductor.

Ball Grid Array

Ball Grid Array (BGA) involves attaching an array of solder balls to the underside of the device to form connections to the PCB, allowing for high-density packaging. They are commonly used in high-performance applications, such as Central Processing Units (CPUs), Graphics Processing Units (GPUs) and telecommunications equipment.

Chip-on-Board

Chip-on-Board (CoB) is a packaging technology where bare semiconductor chips (also known as ‘dies’) are directly attached to a printed circuit board. The chips are wire-bonded to the board, and then encapsulated with a protective material. This type of electronic packaging is traditionally used in applications where space is limited, such as LED lighting and sensors.

Flip Chip

Flip Chip packaging involves flipping the die upside down and soldering it directly to the PCB, allowing for a smaller footprint and better thermal performance. They are used in high-performance computing and Radio Frequency (RF) applications.

Ceramic Packages

This type of electronic packaging is made from ceramic materials and provides excellent thermal performance. Typically hermetically sealed to ensure effective insulation, ceramic packages are used in high-reliability applications, such as military and aerospace electronics.

Leadless Chip Carrier

Leadless Chip Carrier (LCC) takes the shape of a flat package without leads, allowing for a smaller footprint. Common uses include telecommunications and automotive electronics.

Embedded Die Packages

In Embedded Die Packages, the die is installed within the PCB material itself. They are used in advanced packaging solutions for compact and high-performance electronics, such as mobile devices and wearable technology.

Enclosures

Enclosures are protective housings designed to safeguard complete electronic systems. Made from materials such as metal, plastic or composites, they come in various shapes and sizes tailored to the device’s needs. Metal enclosures often feature a sleek finish, while plastic ones can be moulded into intricate designs with ventilation holes for thermal management.

Enclosures are crucial for consumer electronics such as televisions, laptops and gaming consoles, protecting internal components from moisture, dust and physical damage. They also support industrial equipment, telecommunications devices and medical instruments, ensuring reliability and durability in various applications.

Modules

Modules are pre-assembled functional units that integrate multiple components into a single package. They can vary in size and design, often featuring a compact layout with connectors for easy integration into larger systems. Modules may include antennas, sensors or other specialised components housed in a protective casing.

Typically, this type of electronic packaging is widely used in applications like RF modules for wireless communication in smartphones and sensor modules in Internet of Things (IoT) devices. They simplify assembly, enhance functionality and accelerate the development process, making them essential in consumer electronics, automotive systems and industrial automation.

Why Electronic Packaging is Important

Electronic packaging plays a crucial role in the performance, reliability and longevity of electronic devices.

Firstly, it provides protection against environmental factors, such as moisture, dust and physical impact, which can lead to component failure.

Secondly, effective packaging ensures proper thermal management by dissipating heat generated during operation, preventing overheating that can impair functionality.

Thirdly, electronic packaging facilitates mechanical support, ensuring that components remain securely in place during transportation and operation. This also aids in connectivity, enabling seamless communication between different electronic parts.

Finally, aesthetically pleasing designs enhance user experience, making devices more appealing to consumers.

What to consider when selecting an electronic packaging type

When selecting a type of electronic packaging, purchasing managers, product designers and engineers of electronic devices should consider the following top five factors:

1. Protection and Durability – the packaging must provide adequate protection against environmental factors such as moisture, dust and mechanical stress. The choice of materials and design must ensure that the packaged components can withstand the intended use conditions, including temperature fluctuations and physical impacts.

2. Thermal Management – effective thermal management is crucial to prevent overheating of electronic components during operation. The packaging design should facilitate heat dissipation through features like heat sinks or thermal interface materials, ensuring optimal performance and longevity of the devices.

3. Size and Form Factor – the dimensions and shape of the packaging must fit the overall design and application requirements of the electronic device. Compact designs may be necessary for handheld devices, while larger enclosures may be required for industrial applications, influencing the selection of electronic packaging type.

4. Electrical Performance – the packaging must support optimal electrical performance by minimising electromagnetic interference (EMI) and ensuring signal integrity. This involves considering the materials used, layout design and any shielding requirements to enhance the overall functionality of the electronic device.

5. Cost and Manufacturability – cost-effectiveness is a key consideration in selecting electronic packaging type. The choice of materials, manufacturing processes and assembly methods should align with budget constraints while ensuring quality and reliability. Additionally, ease of assembly and scalability for production must be evaluated to streamline manufacturing processes.

Electronic packaging plays a pivotal role in PCB assembly

With various types of electronic packaging, such as IC packages, enclosures and modules, each serving distinct applications, manufacturers can optimise performance and reliability. By understanding the importance of protection, thermal management and electrical performance, stakeholders can make informed decisions. As technology continues to advance, innovative electronic packaging solutions will remain integral to the evolution of electronic devices across diverse sectors.

MPE Electronics is an established and experienced contract electronics manufacturer specialising in PCB assemblies and full box build assembly for a wide range of commercial and industrial businesses.

To find out how MPE Electronics’ PCB manufacturing and assembly services can benefit your business, contact our expert and friendly team on +44 (0)1825 764822 or enquiries@mpe-electronics.co.uk.