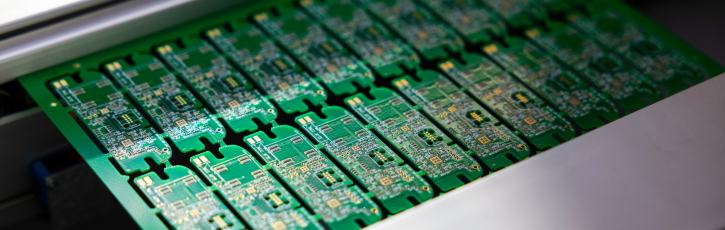

In a world seemingly dominated by high-density multilayer boards, the humble single sided PCB often gets overlooked. But for many applications, from consumer electronics to industrial controllers, single sided PCB assembly remains not just relevant but crucial. In today’s supply chain climate, where cost, speed and design simplicity are everything, single side PCBs can offer a competitive edge you might be missing.

Need fast, reliable single sided PCB assembly? Talk to our team.

What are single sided PCBs?

A single sided PCB is the most basic type of printed circuit board – featuring a single layer of conductive material on one side and components mounted only on that same side. It’s a straightforward, cost-effective solution for electronic assemblies that don’t require complex routing or multi-layer interconnections.

Developed in the 1950s, the first commercial PCB was a single sided PCB. Despite the ensuing decades of innovation in multilayer and HDI (High Density Interconnect) board technologies, this original design is still found in millions of electronic devices today, from thermostats to kitchen appliances to industrial controllers.

The ongoing popularity of single sided PCB assembly is rooted in practicality. When a design doesn’t require the complexity of multilayer routing, opting for a simpler board often results in faster production, lower costs and greater reliability. In many applications, simplicity isn’t a compromise – it’s the smartest solution.

What are the advantages of single sided PCBs?

As the most basic PCB type, single sided PCBs offer a range of practical advantages that make them a smart choice for many electronic designs.

Simplicity

With components and copper traces on just one side, single sided PCBs are straightforward to design, assemble and test. This simplicity reduces the likelihood of layout errors and shortens production timelines. Whether using traditional through-hole components or compatible surface-mount parts, single side PCB assembly is straightforward and well-suited to automated processes like wave soldering – maintaining efficiency without adding complexity.

Low Density

Single-sided boards are ideal for low-density circuit layouts, where there are fewer components and more space between traces. This approach is perfect for designs with minimal component complexity, allowing for easier routing and less interference between signals. With fewer layers and simpler construction, these boards are particularly well-suited for applications like power supplies, LED lighting and consumer electronic devices.

Cost-Effective

As single-sided PCBs require fewer materials, layers and production steps, their assembly process is one of the most cost-effective. The streamlined design and simplicity translate directly into lower material costs, reducing both the complexity and time required for production. Additionally, the reduced tooling and set-up costs make single-sided PCBs highly attractive for high-volume runs, where efficiency and cost savings are paramount. This makes them not only an economical solution for simple designs but also a smart choice for large-scale manufacturing, where scalability and consistent performance are key factors.

Faster Turnarounds

The simplified layout and reduced manufacturing complexity of single-sided PCBs significantly accelerate prototyping and production cycles. With fewer components to place and simpler assembly processes, these boards can be quickly designed, tested and manufactured, cutting down on the time it takes to bring a product to market. This is particularly advantageous for industries where speed-to-market is critical, enabling companies to respond faster to market demands, make necessary design adjustments and launch products swiftly. Whether for rapid prototyping or high-volume production, single-sided PCBs ensure a quicker turnaround, giving businesses a competitive edge in fast-paced industries.

High Reliability

One of the key advantages of single-sided PCBs is their inherent reliability. With fewer interconnections and simpler layouts, there are fewer points of potential failure, resulting in a more stable and dependable circuit. This makes single-sided PCBs an excellent choice for applications that require long-term performance without frequent maintenance or failure. Whether used in power supplies, consumer electronics or other low-complexity devices, the simplicity of single-sided designs ensures robust operation in even the most demanding environment. The reduced number of connections also means less chance of wear and tear, contributing to a longer lifespan and higher overall reliability of the finished product.

What are the disadvantages of single sided PCBs?

While single-sided PCBs offer benefits like cost-effectiveness, simplicity and reliability, they also have limitations. These constraints make them suitable for basic, low-density applications but less ideal for complex or high-performance electronics. Below, we highlight the main drawbacks of single-sided PCBs.

Limited Component Density

As components can only be mounted on one side of the board, the available space for components is limited. This restriction makes single-sided PCBs less ideal for designs that require a high component count or tightly-packed interconnects. More complex designs often require multi-layer or double-sided PCBs to accommodate the necessary components.

Lack of Design Flexibility

Single-sided PCBs are best suited for simple, low-density applications. As products evolve and require more functionality, the limitations of single-sided boards become apparent. These boards lack the flexibility needed for complex designs that require high-speed signals or multiple layers of routing, forcing designers to consider multi-layer alternatives.

Signal Integrity and Power Issues

Single-sided boards can struggle with maintaining high signal integrity, especially for high-speed or high-frequency circuits. The limited space for trace routing can result in longer traces, which may negatively impact the performance of the circuit. This makes single-sided PCBs less suitable for applications that require precise signal control or power management.

Heat Dissipation Challenges

With components confined to a single side, managing heat dissipation becomes a concern, especially in high-power applications. Heat generated by components can be harder to dissipate effectively, potentially leading to overheating or reduced performance. Multi-layer boards, in contrast, allow for better heat distribution.

Less Suitable for High-Performance Applications

For industries that require high precision and reliability, such as medical or aerospace, single-sided PCBs may not meet performance standards. These applications typically demand more advanced designs that can only be achieved with multi-layer or double-sided PCBs, which offer better performance and reliability.

Typical single sided PCB applications

Single sided PCBs are used in a variety of everyday electronics because these types of assemblies are ideal for low-density, low-complexity applications, where space and performance demands are relatively minimal. Below are a few common applications where single sided PCBs are frequently employed:

- Household Appliances: Such as microwaves, toasters and washing machines, where basic functionality is required with minimal component complexity.

- Power Supplies: For low to medium-power applications, providing efficient circuit layouts for regulating voltage and current.

- LED Lighting: Ideal for low-power LED circuits, offering efficient and cost-effective designs for lighting solutions.

- Security Systems: In alarm systems and CCTV cameras, providing dependable functionality in low-complexity environments.

- Automotive Electronics: For basic automotive systems, such as lighting controls or simple sensors, where a reliable but uncomplicated design is necessary.

Industry Insight: When to Use Single Sided PCBs

At MPE, we understand that single sided PCBs remain a valuable choice in electronics manufacturing. Despite the rise of multilayer boards, single sided PCBs are still widely used, particularly when cost-efficiency, simplicity and reliability are the top priorities. But when exactly should you choose a single sided PCB over other options?

Single sided PCBs are ideal for applications with low-density component layouts, where space isn’t a premium.

They’re particularly useful for:

- Cost-sensitive designs: When you’re looking to reduce manufacturing costs without compromising on performance

- Simple and reliable applications: Perfect for products where reliability and long-term stability matter more than the miniaturisation or complexity of a multilayer board.

- Quick turnaround times: The simpler design process enables faster prototyping and production cycles, ideal when speed-to-market is essential.

As Nicola Evans, Managing Director of MPE, explains: “Single sided PCBs are often the unsung heroes in the world of electronics. They strike the perfect balance between performance and cost-efficiency, particularly when complex designs aren’t necessary. For many of our customers, they remain the go-to option for applications where simplicity and reliability matter most.”

Selecting a Single Sided PCB Assembly Partner

When choosing a partner for single sided PCB assembly, it’s essential to consider several key factors. Look for a partner with a proven track record in fast-turnaround work, ensuring they can handle large-scale orders efficiently. Additionally, strong process control and IPC-certified quality standards are critical to ensure consistency and reliability across production runs. In-house testing capabilities, as well as Automated Optical Inspection (AOI) is important for detecting defects early and accommodating both small and large production runs.

At MPE, our state-of-the-art facility integrates precision machinery with highly skilled staff, backed by decades of electronics assembly experience. This enables us to consistently deliver quality results regardless of quantity required. We work closely with customers to help them select the optimal PCB for each project, balancing cost, performance and reliability.

Single sided PCBs remain a vital and cost-effective solution for many industries

Despite the rise of multilayer technologies, the simplicity, reliability and affordability of single sided PCBs make them the perfect fit for applications that don’t demand high-density layouts. Whether it’s consumer electronics, power supplies or security systems, single sided boards continue to deliver on performance without the complexity of multi-layer alternatives.

Need single sided PCB assembly? Get in touch with our team today to learn more.

MPE Electronics is an established and experienced contract electronics manufacturer specialising in PCB assemblies and full box build assembly for a wide range of commercial and industrial businesses.

To find out how MPE Electronics’ PCB manufacturing and assembly services can benefit your business, contact our expert and friendly team on +44 (0)1825 764822 or enquiries@mpe-electronics.co.uk.