Printed circuit boards (PCBs) form the backbone of nearly every electronic device today, from smartphones and medical devices to industrial machinery and automotive systems. As electronics become more compact and sophisticated, modern PCB manufacturing techniques have evolved to meet increased demands for precision, complexity, and reliability. For engineers and procurement teams, understanding modern PCB manufacturing is key to ensuring product success, cost efficiency, and quality assurance.

This guide explores the full spectrum of PCB manufacturing processes, industry standards, innovative technologies, and practical insights to help you select the right manufacturing partner and optimise your electronics production.

What is PCB Manufacturing?

PCB manufacturing is the process of transforming a circuit design into a physical board that mechanically supports and electrically connects electronic components. The manufacturing involves several critical stages:

- Preparing the copper-clad laminate

- Etching away unwanted copper

- Drilling holes for through-hole components or vias

- Plating and layering internal circuits

- Applying solder masks and silkscreens

- Conducting quality inspection and testing

Each step demands precision and strict quality control to ensure the final board functions as designed.

Types of PCBs: From Single-Sided to Multilayer

Modern electronic applications require various PCB types to accommodate increasingly complex circuits in limited spaces. Choosing the right PCB type influences manufacturing techniques and cost.

Single-Sided PCBs

Featuring copper tracks on only one side, single-sided PCBs are the simplest and most economical option. They suit low-cost, basic devices with minimal space or complexity needs.

Double-Sided PCBs

With copper on both sides, double-sided PCBs enable more complex circuits and use plated-through holes for electrical connections between layers.

Multilayer PCBs

Multilayer PCBs consist of multiple internal layers stacked between insulating substrates. They support high-density circuits, enhanced signal integrity, and less electromagnetic interference. Layer counts may exceed 50 for demanding applications like telecommunications and aerospace.

Key Stages of Modern PCB Manufacturing

1. Design Preparation and Data Validation

PCB design files, typically in Gerber format, are carefully validated before production. Checks include circuit layout accuracy, drill files, pin assignments, and component footprints. Implementing design-for-manufacturing (DFM) principles optimises production, keeps costs down and reduces errors.

2. Material Selection

Substrate materials are chosen based on thermal, mechanical, and electrical requirements. FR-4 remains the standard glass-reinforced epoxy laminate. Specialised materials like Rogers laminates are used for high-frequency RF PCBs, while flexible polyimide films support flexible PCB production. There are other options such as CEM-1/CEM-3 (composite epoxy materials) and metal-core substrates (typically aluminium) for better heat dissipation.

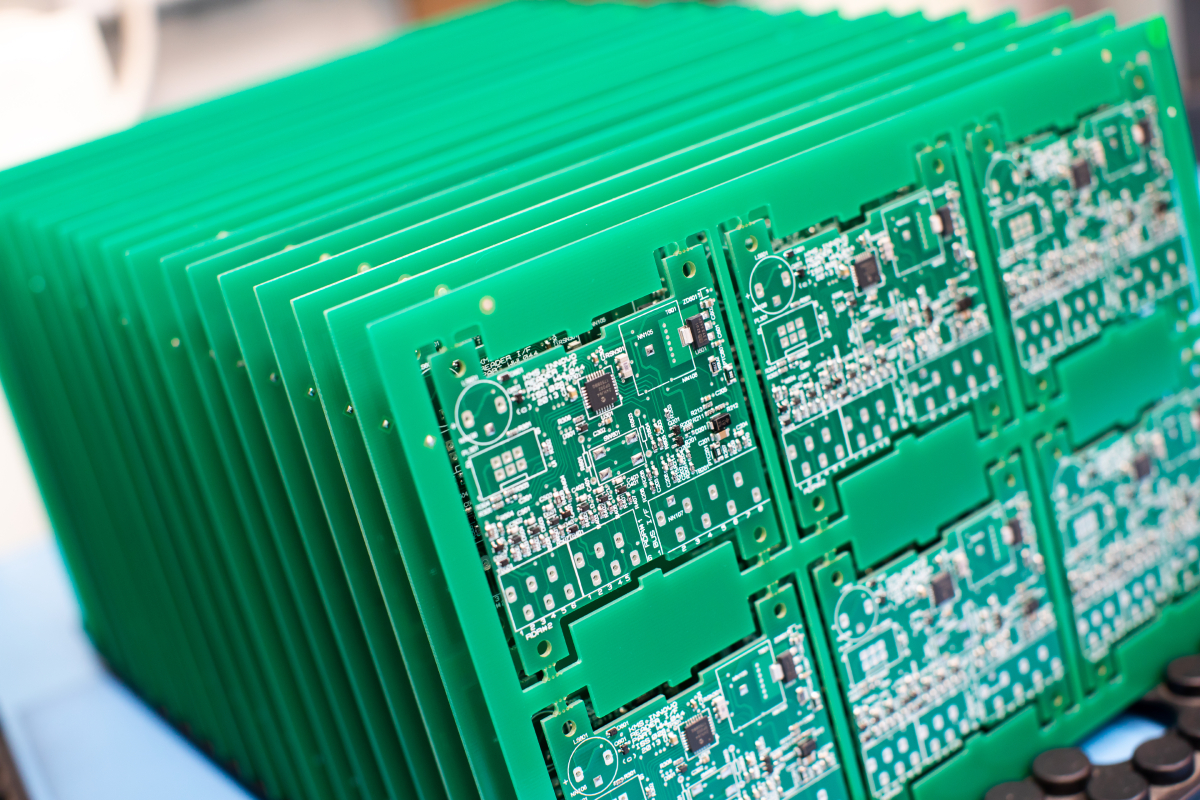

3. Panelisation

Multiple PCB units are grouped into a single panel to improve throughput and reduce costs. Panelisation enhances handling and streamlines testing and assembly operations.

4. Photoresist Application and Imaging

A photoresist layer is applied to copper surfaces using photolithography. Ultraviolet light selectively hardens photoresist through a photomask, leaving unwanted copper exposed for etching. This process requires cleanroom conditions to avoid defects.

5. Etching Copper

Chemical etching removes exposed copper, forming precise circuit traces. Environmentally controlled etchants comply with regulations like the EU REACH directive to reduce hazardous waste.

6. Drilling and Plating

High-precision CNC drills create holes for components and vias. The holes are plated with copper to provide electrical connections between layers. The plating involves cleaning, electroless copper deposition, and electroplating to ensure durable conductivity.

7. Solder Mask and Silkscreen Printing

A solder mask protects copper tracks from oxidation and short circuits during assembly. Silkscreen printing adds component identifiers and logos to assist assembly and ensure traceability.

8. Surface Finish

Surface finishes are selected based on assembly and component needs:

- HASL (Hot Air Solder Leveling): cost-effective but less suitable for very fine-pitch components.

- ENIG (Electroless Nickel Immersion Gold): smooth, durable finish ideal for fine-pitch and high-reliability boards.

- OSP (Organic Solderability Preservative): eco-friendly but shorter shelf-life.

Innovations in Modern PCB Manufacturing

Automation and Industry 4.0

Automation technologies such as robotic handling, automated optical inspection (AOI), and inline electrical testing improve accuracy and throughput. Industry 4.0 approaches, incorporating IoT sensors and real-time analytics, enable enhanced traceability and process optimisation, reducing defects and waste.

High-Density Interconnect (HDI) PCBs

HDI PCBs feature microvias, laser drilling, and sequential lamination to achieve fine-pitch components and dense routing. These technologies are crucial for miniaturised devices like mobile phones and wearables. Manufacturing HDI boards requires specialised expertise due to high complexity.

Flexible and Rigid-Flex PCBs

Flexible PCBs use bendable substrates for designs that fold or twist, common in medical devices and compact gadgets. Rigid-flex combines rigid and flexible sections to meet complex mechanical demands. These require advanced lamination and bending testing, often adhering to IPC standards such as IPC-6013 and IPC-6014.

Environmental Considerations

Sustainability is an increasing focus in PCB manufacturing. Leading manufacturers use sustainable manufacturing practices, including green etching chemistry, cutting hazardous waste and complying with RoHS and WEEE regulations to minimise environmental impact and improve product safety.

Quality Assurance and Testing

Comprehensive quality assurance ensures PCBs meet performance and reliability requirements. Common testing techniques include:

- Electrical Testing: Checks for continuity and isolation using “bed of nails” or flying probe testers, with flying probe preferred for prototypes.

- Automated Optical Inspection (AOI): Detects surface defects, solder mask problems, and misalignments in 2D and 3D.

- X-ray Inspection: Examines internal layers and solder joints, critical for complex boards with BGAs and buried vias.

- Functional Testing: Powers the assembled board under simulated conditions to verify correct operation.

Reputable manufacturers provide full test reports and certifications, demonstrating compliance with IPC standards.

Choosing the Right PCB Manufacturing Partner

Partnering with a qualified electronics manufacturing services (EMS) provider with proven PCB expertise influences your project’s success. Consider these factors:

- Technical Capability: Ability to manufacture your PCB type, layer count, and complexity.

- Certifications: ISO 9001, ISO 13485 (medical), or automotive standards like IATF 16949 indicate quality management.

- Manufacturing Flexibility: Supports prototypes, small runs, and volume production seamlessly.

- Quality Control: In-house testing, traceability, and comprehensive process documentation.

- Customer Support: Responsive technical collaboration and communication.

MPE Electronics offers extensive experience in PCB assembly and box build, with rigorous quality controls and sector certifications. We support diverse industries including automotive to defence.

Summary: The Future of PCB Manufacturing

As electronics continue to advance towards greater miniaturisation and performance, PCB manufacturing must follow suit, to innovate with automation, smarter processes and new materials tailored for 5G and IoT devices. Understanding these trends, selecting suitable PCB types and working with experienced manufacturers like MPE Electronics are key to delivering reliable, cost-effective products to market.

Contact MPE Electronics today to explore how our turnkey manufacturing solutions can support your PCB assembly and full production requirements. Contact us on +44 (0)1825 764822 or enquiries@mpe-electronics.co.uk.