Frequently asked questions about contract electronics manufacturing

At MPE Electronics, we are pleased to answer any questions our clients have. If the answer to your question is not listed below, please get in touch with a member of our team for more details.

Sales and Quoting

How long does it take from Request For Quote (RFQ) for you to complete a quote?

This can vary depending on the size of the RFQ, the number of components on the Bill Of Materials (BOM) and capacity in the quotes department at time of RFQ. Generally we aim to submit our quotation within 2-4 weeks after receiving an RFQ.

What information do you require from a potential customer to provide them with a quote?

We would need a full data pack to be supplied, which should include Gerber files for the bare PCB and BOM (Bill of Materials), along with any assembly drawings and build instructions, where necessary, as well as the quantity that a quotation is required for.

IS THERE A MINIMUM SPEND REQUIREMENT FOR QUOTATIONS OR ORDERS?

No, MPE Electronics does not have a minimum spend requirement for our customers, for either quotations or orders.

Manufacturing, stock and capabilities

Do you offer any design capabilities?

We don’t offer any design capabilities ourselves but work closely with a company that can help with any design requirements you may have; we can then look at quoting on the electronics manufacturing side for prototypes through to production volumes.

Do you offer Kanban / stock holding?

This is something that can be discussed based on expected volumes.

What’s the typical quantity range of PCB assemblies you can offer to manufacture?

We can manufacture typical batches from as little as 1 (prototype stage) up to 10,000.

What is your average lead time for manufacture?

Once all componentry has been received, the average lead time for manufacture can be between 2-4 weeks depending on batch quantity and number of components per assembly.

Componentry lead time in the current supply market generally varies from existing stock to 52 weeks in extreme cases. The lead time will be advised at the time of quotation, taking in consideration the lead time for components and the manufacture time.

PCB Quality Control

What build standards do you work to?

All shop floor staff are IPC-A-610 class 3 certified and we are ISO 9001:2015 approved.

What inspection processes do PCB assemblies go through?

All surface mounted assemblies are 100% Automated Optical Inspection (AOI) tested and all through hole components also get a 100% visual inspection prior to being shipped out. Find out more about our inspection and testing processes here.

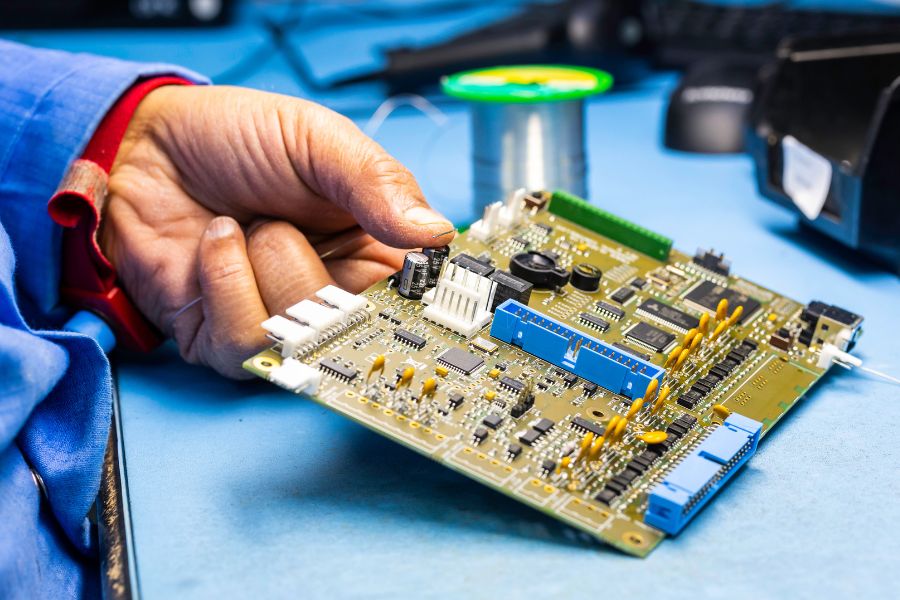

Surface Mount Technology (SMT) and Through Hole Assembly

What is the difference between SMT and Through Hole Assembly?

| Through Hole assembly | Surface Mount Technology (SMT) | |

| Popularity | More prevalent in the assembly of larger electronic components, such as transformers, connectors, semiconductors and electrolytic capacitors. | The most widely used PCB assembly process. Most available electronic components can be mounted on circuit boards using this technology. |

| Process | Manual process but can also be automated. Pre-formed components are threaded through pre-drilled holes and soldered onto circuit boards, either by hand or using an automated process. | Fully automated process. Components are pasted and soldered to circuit boards, using fully automated production lines. |

| Features | Higher rated components are sometimes available compared to the surface mount counterparts. | Can be used to place components on both sides of a circuit board and it removes the need to drill holes through the PCB. |

| Advantages | Provides a more robust mechanical bond between the circuit board and the application which enhances strength and security, making it ideal for aerospace and defence applications, within equipment that withstands extreme stress and temperatures. It also has a fast and uncomplicated prototyping. | Perfect for the assembly of smaller, lighter, and more powerful PCBs that require a high degree of customisation. It also provides a greater uniformity of component soldering and allows for greater control of the width of route traces, which in turn reduces mechanical heat and noise, therefore improving the quality and performance of a product. |

What determines the choice of assembly process (SMT vs Through Hole)? Is it subject to the customer’s requirements?

Fluid communication with our customers is always key to an efficient and seamless assembly process. We are very attentive to our customers’ specific requirements and we manufacture to your design. Therefore MPE does not decide whether we use surface mount or through-hole assembly. The PCB layout is totally different for each of the technologies, which means that we build what the customer has designed.

PCB Assembly

Precise, reliable PCB assembly to your exact requirements.

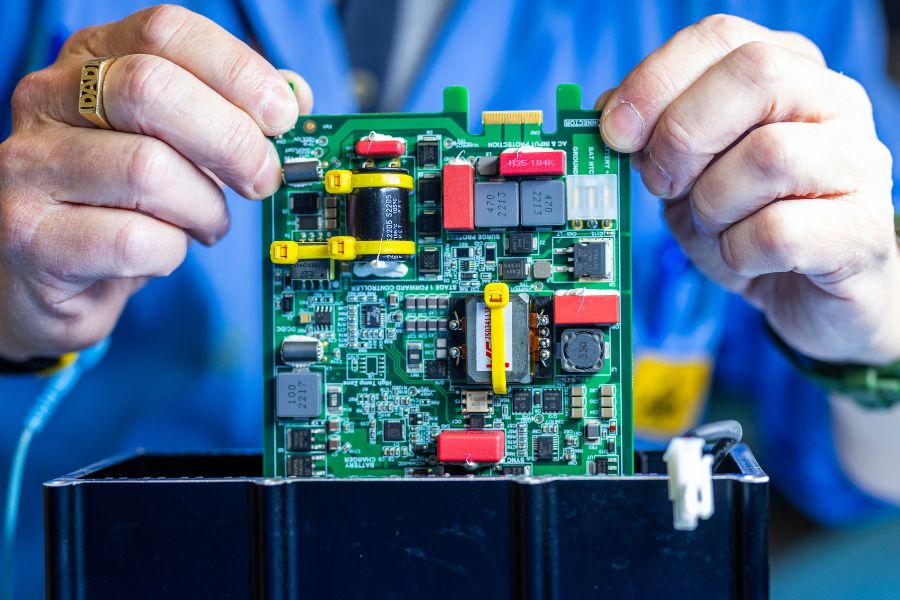

Box Build Assembly

Optimise your supply chain with our turnkey assembly service.