Guide To PCB Testing

Rigorous PCB testing is a vital part of the PCB assembly process and a variety of testing methods are available, if required, to make sure that every product works correctly and remains safe and reliable.

Different products require different levels of testing, for example, products or assemblies that are used in harsh environments need more extensive testing as there is a large variety of conditions they might face, ranging from extreme temperatures to volatile movement. On the other hand, some PCBs may require more basic levels of testing to ensure their effectiveness.

PCB testing is often outsourced because product makers do not have the in-house resources or the desire to carry out certain key processes. At MPE Electronics, we are a UK electronics manufacturer which is always pleased to assist.

What types of PCB testing are there?

The most common types of PCB testing services are environmental testing, automated optical inspection (AOI) testing and customer-specific functionality testing.

Environmental testing involves the testing of circuit boards in extreme conditions. These conditions are simulated in an environmental test chamber.

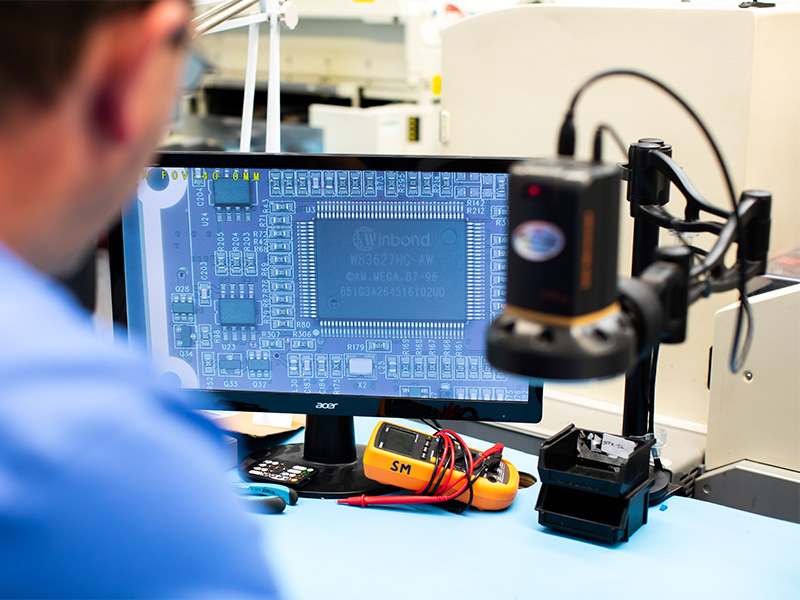

AOI testing is an automated visual inspection process.

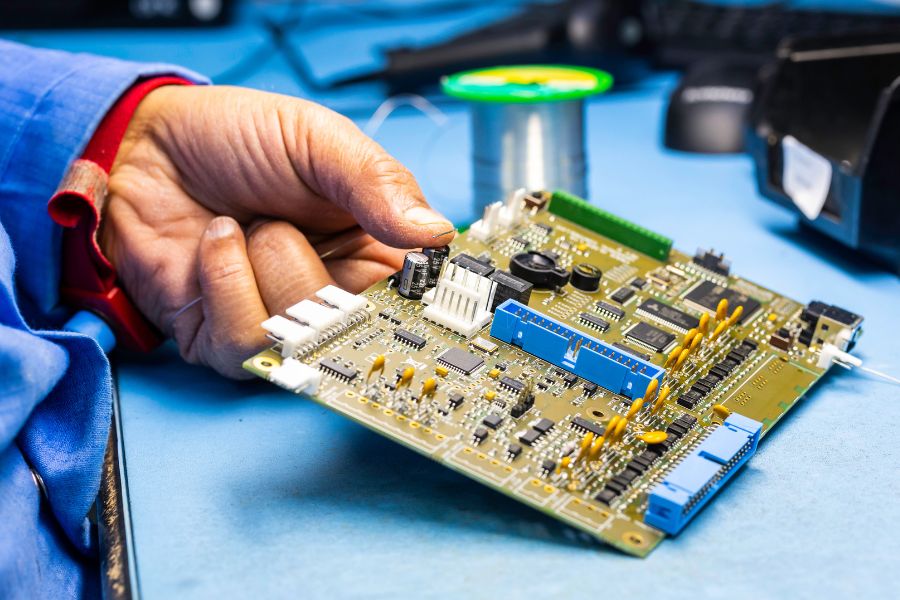

Customer-specific functionality testing designed according to unique product characteristics and can be carried out manually (bench-top testing) or automated (ATE testing).

The PCB testing service you need should be available from your electronics manufacturer as either a standalone service or part of a larger PCB assembly service.

It should not have an impact on the performance or appearance of the PCB assembly, however, if you want your PCB assemblies to look at their best post-testing, you may be able to make use of your contract manufacturer’s cleaning process.

What to look out for

It’s important to find out whether a potential manufacturing partner performs testing on a batch or all-board basis. To ensure consistent quality, you should only use a PCB assembly manufacturer that performs testing on all of your boards.

It is also vitally important to choose a reliable electronics manufacturing partner to ensure your entire PCB production is at its best.

PCB testing is always factored into MPE’s project plans and all communication is maintained with any suppliers, to ensure customers receive their products on time and to the correct technical specification.

We’re here to help

If you’re looking for a PCB supplier, ready and prepared to adapt to your specific or changing needs, please contact us at

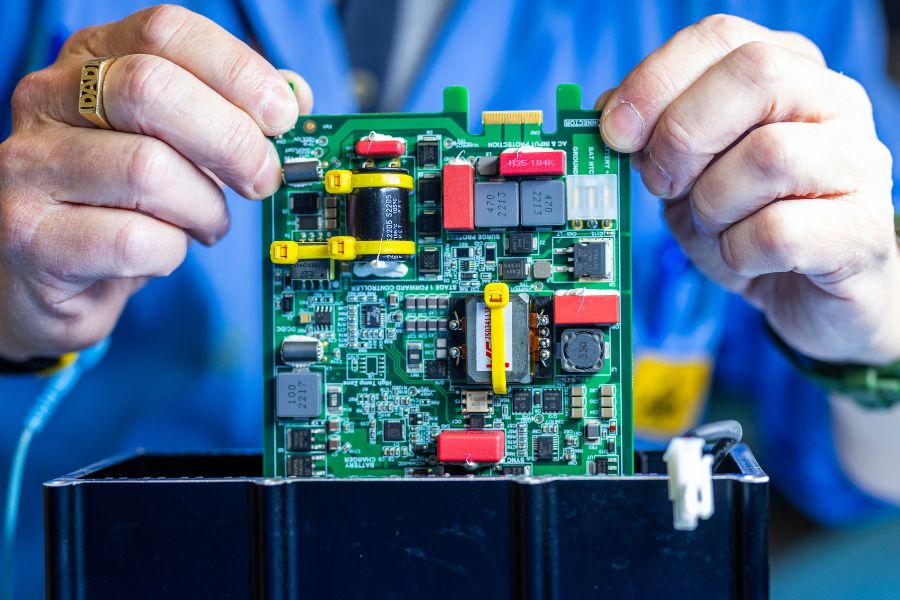

PCB Assembly

Precise, reliable PCB assembly to your exact requirements.

Box Build Assembly

Optimise your supply chain with our turnkey assembly service.