Guide To Through Hole Assembly

Through Hole Assembly is the electronics manufacturing process whereby pre-formed components are threaded through pre-drilled holes and soldered onto circuit boards.

It was considered to be a major part of the electronics industry in the 1950s and 1960s until industry developments forced it to make way for the emergence of Surface Mount Technology in the late 1980s.

Although Through Hole Assembly remains a less popular alternative to the more widely used Surface Mount Technology (SMT), it still has its importance in modern day electronics.

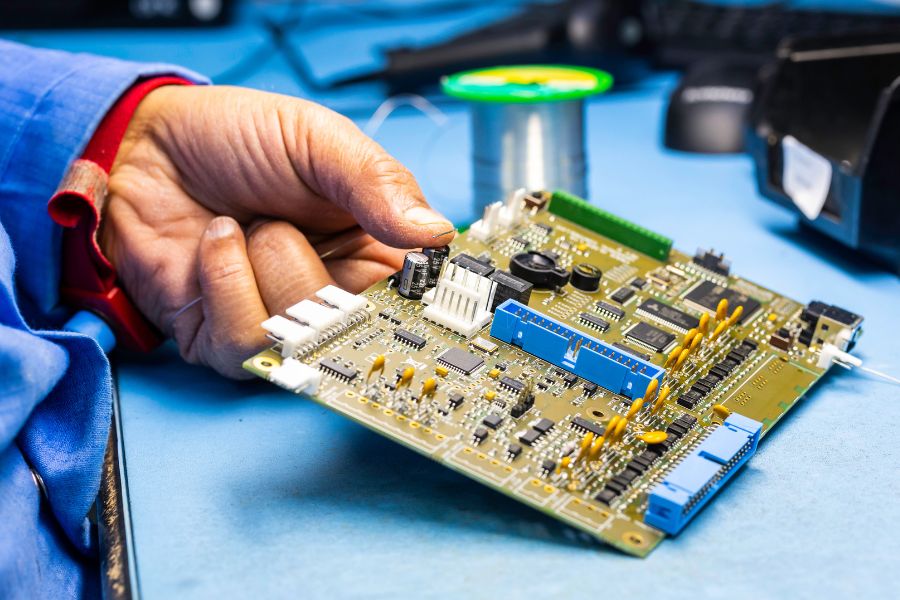

Through Hole Assembly is, for example, used in larger electronic components, such as transformers, connectors, semi-conductors and electrolytic capacitors, because it creates a more robust mechanical bond between the circuit board and the application.

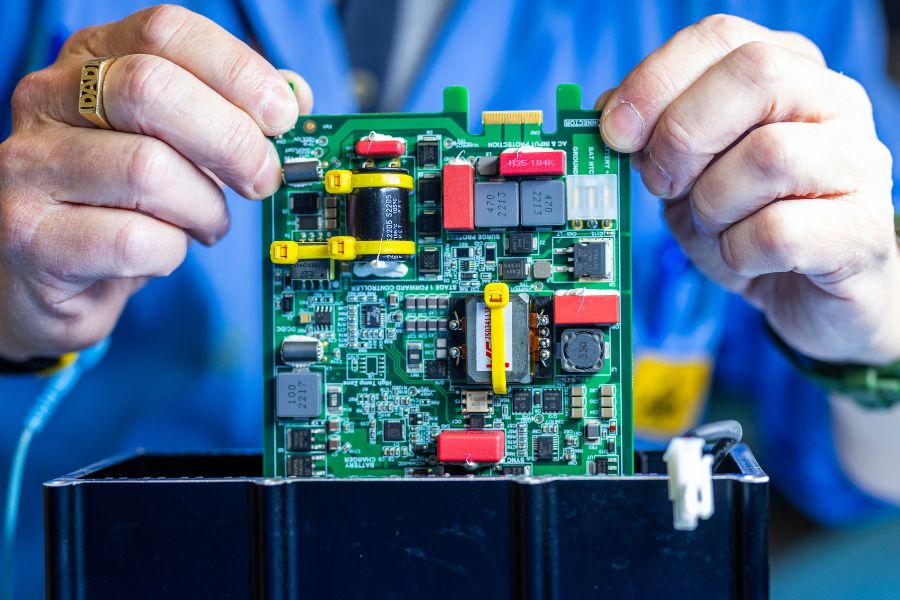

The enhanced strength and security also makes Through Hole Assembly the preferred option for manufacturers in aerospace and military sectors, where the component may come under greater physical stress than normal.

A decision is made to use this process in specific circumstances where it is considered to be more appropriate. Careful consideration must always be given to which process to choose.

Through Hole Assembly Process

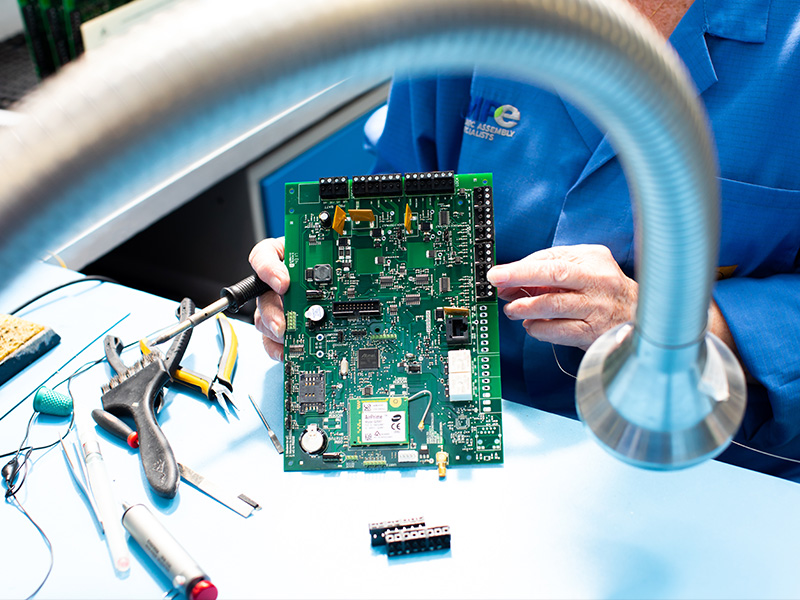

The Through Hole Assembly process is usually a manual one, but it can also be automated.

Pre-formed leaded components (axial and radial leads) are manually inserted through pre-drilled holes and soldered onto circuit boards, either by hand or using an automated process with a flow solder machine. The techniques and materials used are dependent on the design of the board, the batch size and the intended usage.

These components are particularly useful during the prototyping and testing phases, because they can easily be adjusted or replaced.

Components are also sometimes available which are more highly rated than the Surface Mount Technology counterparts.

Through Hole Assembly Benefits

Being aware of the right time to use Through Hole technology is vital for any application. For this reason, it’s always a good idea to consult electronics experts, as making the wrong decision between Surface Mount Technology and Through Hole Assembly could have a huge effect on the whole PCB assembly process. This could mean extra costs and a reduction in the performance and quality of the application as a whole.

In environments where the circuit board will be placed under more stress, through hole assembly is considered to be the most effective option, because of its more robust nature. This has to be its biggest benefit.

In summary, Through Hole PCB assembly is well suited to:

high levels of stress

high speeds

extreme temperatures, both hot and cold

high-voltage conditions

fast and straightforward prototyping

We’re here to help

If you’re looking for a PCB supplier, ready and prepared to adapt to your specific or changing needs, please contact us at

PCB Assembly

Precise, reliable PCB assembly to your exact requirements.

Box Build Assembly

Optimise your supply chain with our turnkey assembly service.