Guides

Electronics Manufacturing Guides

Our customers can relax in the knowledge that they are firmly in the hands of PCB manufacturing experts at MPE Electronics. For anyone interested to find out more, we have created a series of guides to show how some of our processes work.

If you can’t find the information you need, please feel free to contact a member of our friendly team on: (01825) 764822 / Email: enquiries@mpe-electronics.co.uk

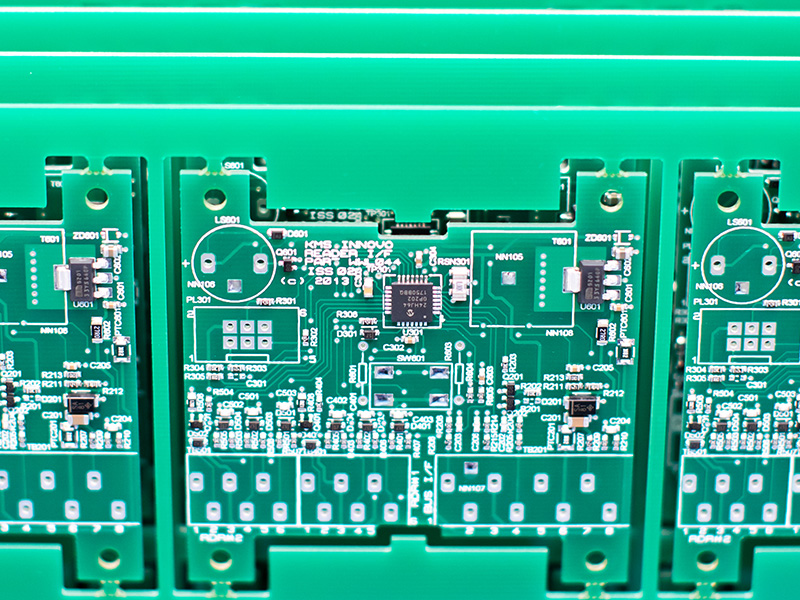

Guide To Surface Mount Technology

Surface Mount Technology (SMT) is the method used to paste and solder components directly to circuit boards using automated production lines. An electrical component mounted in this way is referred to as a surface-mount device (SMD). The majority…

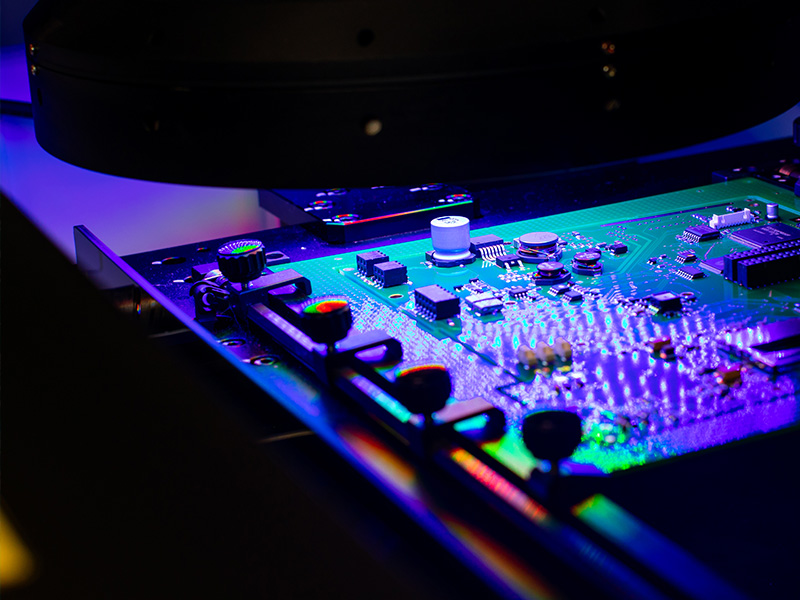

Guide To PCB Testing

Rigorous PCB testing is a vital part of the PCB assembly process and a variety of testing methods are available, if required, to make sure that every product works correctly and remains safe and reliable. Different products require different levels…

Guide To Through Hole Assembly

Through Hole Assembly is the electronics manufacturing process whereby pre-formed components are threaded through pre-drilled holes and soldered onto circuit boards. It was considered to be a major part of the electronics industry in the 1950s and…

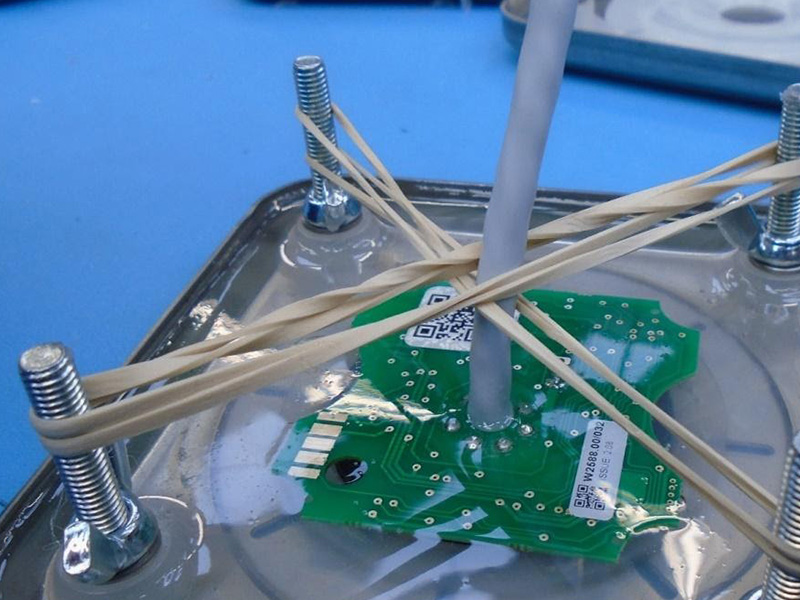

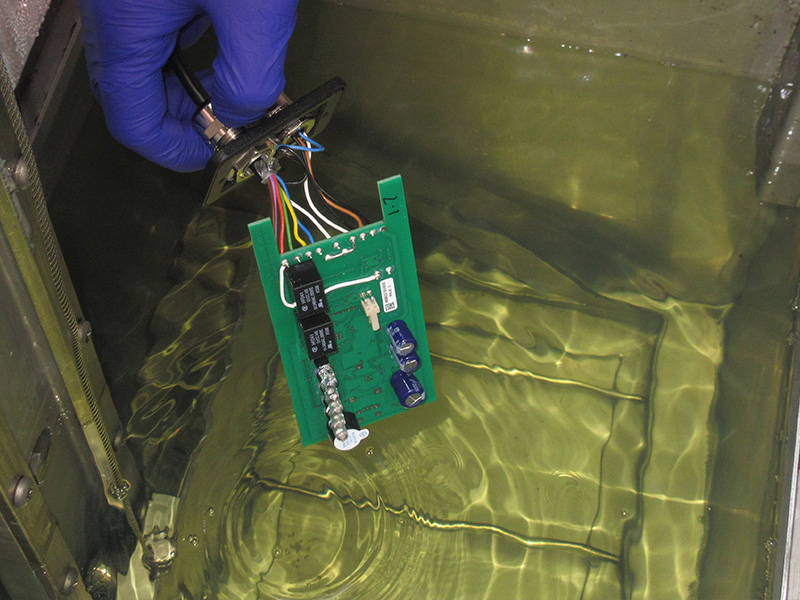

Guide To Electronics Potting

Electronics potting is a widely used method of protecting and encapsulating circuit boards and components, or entire devices in a protective material to protect them from moisture, dust and other contaminants. The circuit board is placed inside a…

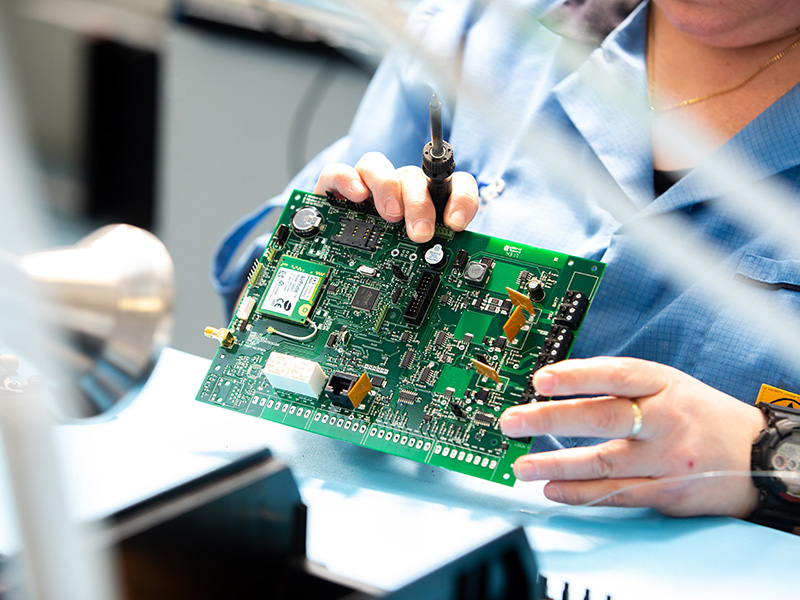

Guide To PCB Soldering

PCB soldering is a critical process in electronic manufacturing that involves attaching electronic components to a printed circuit board using solder. There are two types of soldering processes available – wave soldering and hand soldering . Wave…

Guide To PCB Coating

PCB Coating is carried out to protect the Printed Circuit Board (PCB) from various environmental factors such as moisture, dust, chemicals, and temperature extremes. It also provides insulation and enhances the overall durability of the PCB. As such,…