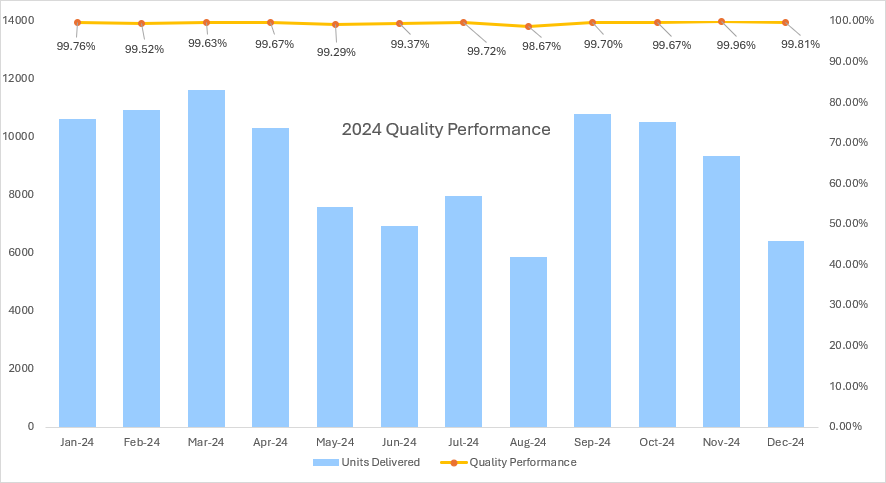

Quality

Uncompromising Quality Control & Standards

Quality control is firmly rooted throughout our PCB assembly and box build manufacturing processes. Your PCB assemblies are at the heart of your electronic product, making reliability, safety, longevity, performance consistency and compliance non-negotiable pillars of our services.

There is nothing more vital to MPE than the attention we give to electronics quality control and PCB quality control. Our reputation is built on our pursuit of the highest standards.

Class 3 Quality

MPE is a specialist manufacturer of high reliability PCB assemblies with longer lifecycles and fail-proof quality, with a production team who are all IPC-A-610 trained and certified, thanks to our full-time, in-house certified IPC trainer.

All products are manufactured and supplied to IPC -A-610 Class 3 standard and every board is inspected individually. Our team does not batch inspect any of our products and we pride ourselves on our first-time pass rate.

IPC-A-610 includes both Class 3 and Class 2 criteria. Class 3 encompasses electronic products and devices designed for critical and demanding operational conditions, where consistent and reliable performance is imperative. These applications, such as life support systems or flight control mechanisms, cannot tolerate downtime and must perform when required. Printed circuit boards falling within this classification are well-suited for situations demanding a high level of assurance and essential functionality.

Certifications

ISO 9001 is a globally recognised standard for quality management. As an officially ISO 9001 certified supplier, we are committed to implementing and maintaining manufacturing and other processes, as well as the continuous training of our team, to reliably deliver an impeccable level of quality of products and services every time.

MPE Electronics also complies with the following regulations:

Restriction of Hazardous Substances (RoHS)

Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH)

By adhering to RoHS and REACH during the assembly of all of our products and services, MPE actively contributes to protecting human health and the environment from the risks posed by chemicals and harmful substances involved in electronics manufacture.

All of MPE Electronics’ certifications are available below for your easy reference:

Effective and Efficient Procurement

To maximise the performance of your electronic product, our in-house purchasing team ensures all components meet the standards previously defined within the pre-manufacture specification.

Electronics procurement is complex, and we are proud of the expertise and skill of our team. Developing and maintaining strong working relationships with an array of suppliers, our procurement specialists hand pick the most appropriate supplier for the range of components or manufactured items that are to be purchased.

We have continual access to industry specialised software containing global stock availability, enabling us to forecast and reduce lead times and cost wherever applicable. As electronic procurement perpetually evolves, we endeavour to update this software as part of our product continuity management service.

Supply Chain Management that drives Quality Control

To ensure all of our products meet IPC Class 3 Quality standards, our team meticulously documents and stores every component, with the specific handling requirements of each diligently entered into our engineering database.

Our in-house Enterprise Requirement Planning (ERP) system informs our procurement specialists of the requested and expected delivery date of each component. This enables our production team to effectively plan and allocate capacity, ensuring timely delivery of your PCB assembly.

Contact our specialist team to discuss your PCB assembly & Box Build requirements

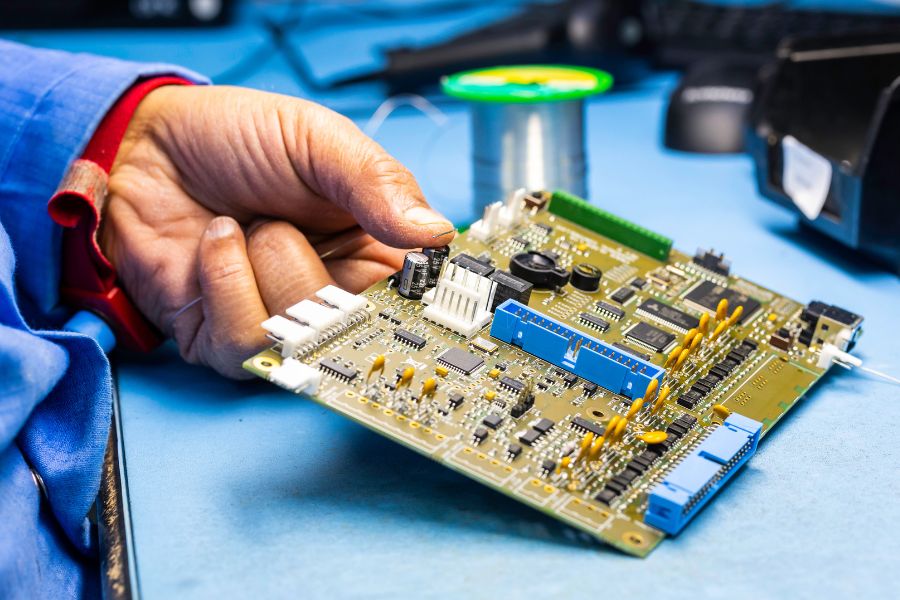

PCB Assembly

Precise, reliable PCB assembly to your exact requirements.

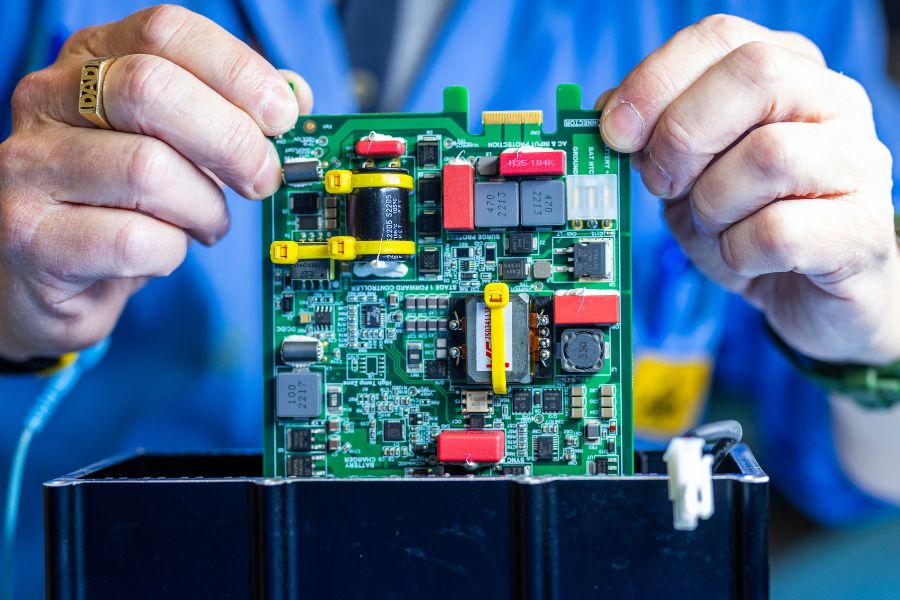

Box Build Assembly

Optimise your supply chain with our turnkey assembly service.