Electronics Packaging

The next critical phase after PCB assembly is the packaging electronics stage. This process ensures that your newly assembled printed circuit boards and enclosed assemblies are carefully and securely packaged, safeguarding them against potential damage, guaranteeing their safe arrival at the next stage of the manufacturing or dispatch process.

What’s the difference between packaging for electronics and electronic enclosures?

We provide a extensive electronics packaging service, including

The selection of high-quality packaging materials to ensure durability and longevity of your assemblies.

Electrostatic Discharge (ESD) protection to safeguard sensitive components from static electricity.

Moisture barrier packaging, which includes storing components in moisture barrier bags with static shielding. We use a vacuum packer to seal these bags, adding desiccant packs and a humidity card to monitor moisture levels.

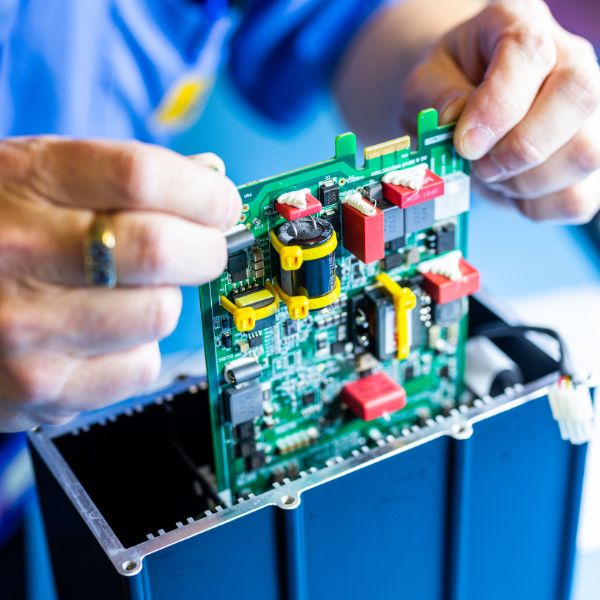

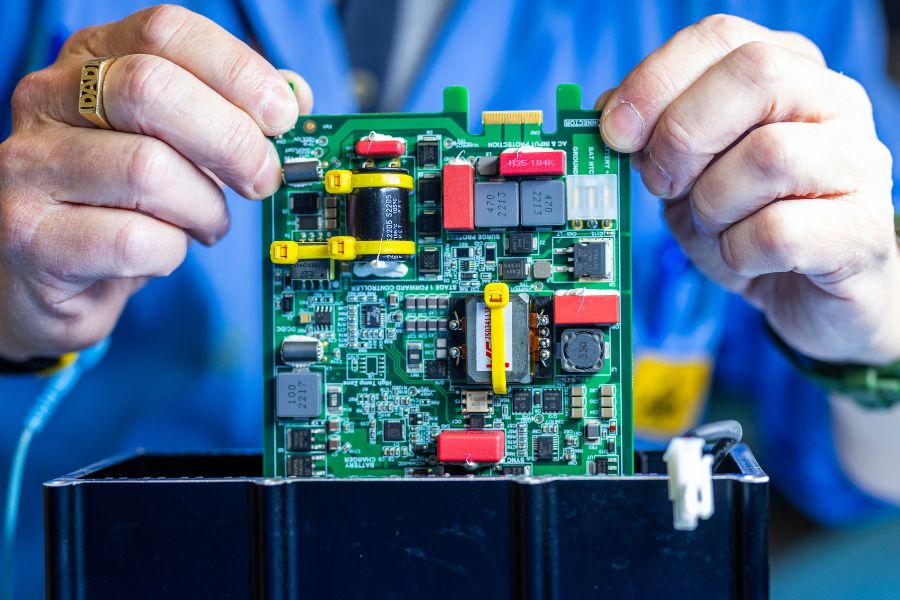

An electronic enclosure is the ‘box’ or chassis into which a PCB assembly is placed to produce the final product, a process known as ‘full box build’ and ‘complete product assembly’. This process includes not only the assembly of the electronic components onto the PCB, but also the integration of the PCB with additional mechanical, electrical and functional elements within the enclosure. Learn more about our box build assembly service here.

Why electronic packaging is crucial for project success

Electronic packaging for assembled PCBs and box build assemblies plays a pivotal role in the performance and longevity of your device. The packaging must protect sensitive components from environmental hazards, such as dust and moisture, and physical damage.

Poorly packed electronics can lead to product malfunctions, reduced lifespan or product failures, potentially damaging your brand’s reputation and incurring costly returns or repairs.

Access our in-house electronic packaging experts

As an MPE customer, you have full access to our integrated electronics packaging service.

By managing the entire packaging process under one roof, we eliminate third-party involvement and reduce risks of miscommunication and compatibility issues. Our advanced manufacturing capabilities allow us to provide packaging that meets the highest industry standards, optimised for the size and weight of your assembled PCBs and box build assemblies.

Committed to quality and compliance, our packaging service includes detailed documentation and testing reports for full transparency. Partnering with MPE means your final electronic device benefits from a seamless, precision-driven approach that enhances performance and reliability.

Our commitment to using recycled packaging

With a strong commitment to sustainability, our electronics packaging service prioritises the reuse of packing materials received from our suppliers and customers. By repurposing these materials to fulfil our packing orders, we significantly cut waste and reduce the need for recycling, which lowers energy consumption and conserves resources. This approach has allowed MPE to lower our reliance on new materials, while maintaining the high level of protection required to protect and safely transport your assemblies.

Learn more about our move towards eco-friendly packaging here.

Logistics & Distribution

Guarantees your high-quality product arrives on time.

Box Build Assembly

Optimise your supply chain with our turnkey assembly service.