Transitioning our client from in-house to outsourced assembly: Earning trust every step of the way

“In the manufacturing world, quality and trust are everything. Our close collaboration with our client has underscored just how impactful a truly client-centred approach can be. When you invest in flexibility, you gain not only loyal clients but also a stronger, more resilient team.”

Nicola Evans, Managing Director, MPE Electronics

MPE’s managing director is referring to a new partnership with an existing client, a communications systems provider, who was in need of specialised assembly support. They shared with us that they were searching for a CEM who could take on the box build of the products that they were building in-house. By adapting our production space, as well as refining our internal systems and processes, we were able to strengthen our partnership with a highly valued client and deliver exceptional results. Explore our case study to see how we adjusted to meet their unique requirements and exceed expectations.

Interested in finding out what a box build is?

See our FAQs section below.

Adapting to exceptional client requirements

Based on discussions between our Sales Director and the client, we came to understand that in order to meet our client’s needs we needed to adapt our facilities. This included establishing a new production area dedicated specifically to their projects and refining our processes to accommodate ‘free-issue’ components – materials provided directly by the client rather than sourced by us.

The client also informed us that they required palletised deliveries, which was a real ‘first’ for MPE. While these adjustments were unique and challenging, they opened doors for us to elevate our client support capabilities, proving that our commitment to flexibility and quality stands strong even under new demands.

Precision from the start

At MPE, we make it our mission to ensure that every new assembly undergoes our rigorous New Product Introduction (NPI) process. This process is typically a collaborative effort from the start, involving key members of both our team and the client’s, including their engineering and production experts. Together, we assess whether we have the necessary skills, resources and tools to bring the product to life, carefully analysing every detail to confirm we can meet the project’s demands.

In this case, our NPI process also emphasised manufacturability. We reviewed the design to see if it could benefit from adjustments for efficiency, cost-effectiveness or improved reliability, offering recommendations as necessary to ensure the highest standards. We also considered whether additional staff training would enhance our process and make production smoother. This level of diligence means that each product we assemble meets our client’s required safety, performance and reliability standards.

Rebuilding our facility to fully embrace our client’s vision

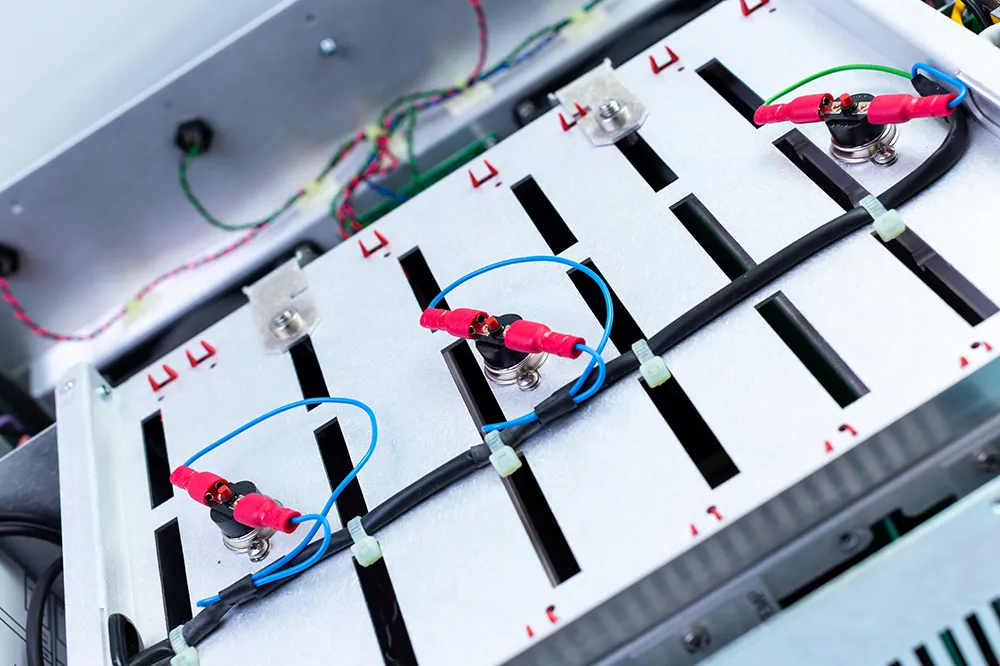

To fully meet our client’s needs, we transformed our manufacturing floor by dedicating an entire production line exclusively to their products. This involved selling our oldest pick-and-place machine to make space, reorganising work benches into a unique assembly line tailored to their requirements, and rerouting electrical lines to power specialised equipment, including the soak test rack supplied by the client. We also installed custom shelving to store their free-issue kits and completed products, ensuring meticulous organisation throughout the assembly process.

These changes allowed us to deliver exceptional results in the short term. However, we knew that the client’s long-term growth – and our own – would mean more space being required. After securing and renovating our new Unit 8 Riverside facility, we established an optimised production line capable of assembly, packing and palletising. Every step of the way, we prioritised seamless support for our client, ensuring that the transition from in-house to outsourced assembly met their timeline and quality expectations.

“Our goal has always been to meet our clients where they are. When our client approached us with their unique requirements, we saw it as an opportunity to not only support their growth but also to refine and expand our own capabilities. Adapting our facility and processes to fit their needs was challenging, but it strengthened our team and allowed us to deliver a level of quality and service that’s become core to our identity.”

Paul Carter, Sales Director, MPE Electronics

Ongoing openness and collaboration

From day one, we built an open, collaborative partnership with our client, welcoming their expertise to shape the success of this project. Thanks to our local proximity, one of their engineers was able to come to our facility to install testing equipment and train our team. Beyond that, we made them feel at home, encouraging them to visit weekly to support our processes and check product samples at each key stage of assembly.

This early commitment to transparency and shared knowledge set a strong foundation. Now, those weekly visits aren’t needed, but we’ve kept the collaboration alive through dedicated monthly meetings with their sales and engineering teams, joined by our sales director, production manager and engineering manager. This structure allows us to maintain a close connection, sharing insights, feedback and updates to keep us fully aligned with their evolving needs.

A hive of activity fueling our client’s growth

Our ability to take over the assembly of PCBs that were once built in-house by our client has become one of our proudest achievements – and it’s only the beginning. We not only met their technical and logistical needs, but we did so while maintaining the highest quality standards throughout the process.

At Unit 8 Riverside, the transformation is evident. The once-empty space has evolved into a thriving hub of activity, dedicated exclusively to supporting our client’s growing needs. The area is a well-oiled machine – assembly lines flow seamlessly, with each phase of production smoothly building on the last, all while meeting deadlines and exceeding expectations. It’s here, in this dynamic environment, that we support the expansion of their product range, adapting quickly and efficiently to each new challenge that arises.

Key learnings

MPE is proud to be able to demonstrate our ability to adapt and grow alongside our clients. By investing in tailored solutions and maintaining open lines of communication, we’ve learned the importance of flexibility and strong relationships when it comes to meeting client expectations.

“This case highlights the importance of adaptability in manufacturing. In today’s rapidly evolving industry, having the infrastructure and mindset to pivot is vital. Our approach to customisation, whether it’s adjusting layouts or adding specific testing stages, has helped us meet complex client needs and set new standards for ourselves.”

Nicola Evans, Managing Director, MPE Electronics

In particular, we’ve learned that the following key traits have been instrumental in fostering such a strong, successful partnership:

Adaptability – by tailoring our production processes and facility layouts to meet specific client needs, we’ve been able to foster long-term relationships and open new opportunities for business growth for both sides.

Collaboration – regular scheduled meetings and open communication are essential for addressing client concerns, capturing real-time feedback and ensuring alignment with client standards.

Commitment – implementing a rigorous quality control process, such as the NPI, ensures that all our clients’ projects meet safety and performance requirements while allowing enough room for process improvements.

FAQs:

What is a box build?

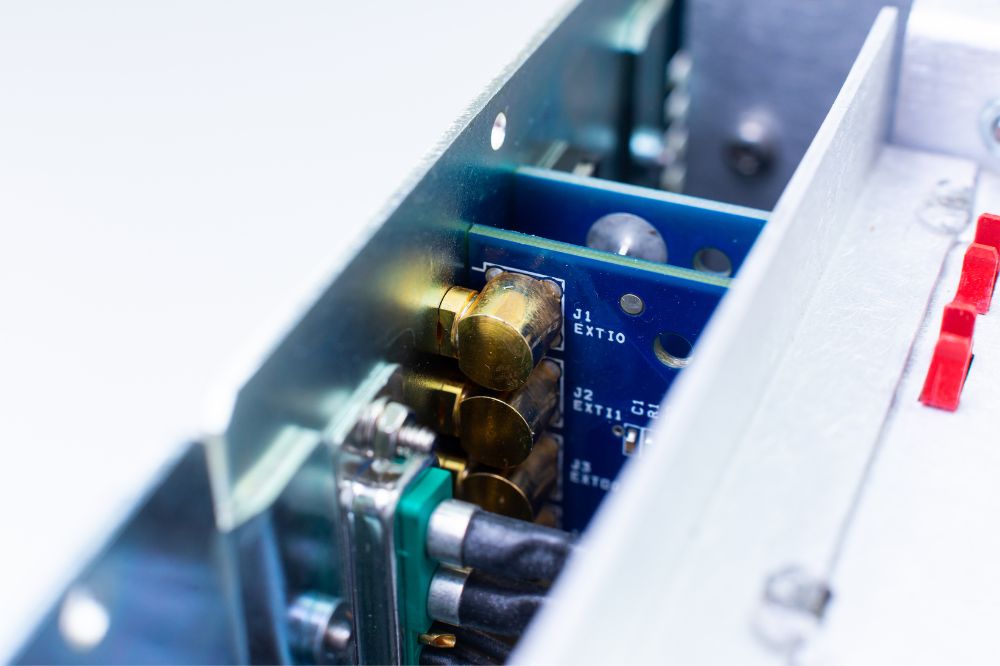

A box build is the final assembly of an electronic product where all components, including the PCB, wiring, and other mechanical parts, are integrated into a finished enclosure. This process involves assembling, testing, packaging and often adding additional functionalities such as user interfaces, ensuring the product is ready for use or shipment.

What is a chassis assembly?

A chassis assembly refers to the framework or housing that holds and supports various electronic components. It is often the structural foundation of a device or system, providing a secure and organised space for the internal parts, such as circuit boards, power supplies and wiring, ensuring everything stays in place while maintaining cooling and safety standards.

What is a soak test rack, and what is it used for?

A soak test rack is used to test the performance and reliability of electronic products under controlled conditions for extended periods. The device is powered on and subjected to typical operational stress, allowing engineers to identify any weaknesses or faults. This test is crucial for ensuring long-term product stability and verifying functionality before deployment.

Why aren’t ‘free issue’ components more widely accepted?

‘Free issue’ components are materials supplied by a client, rather than sourced by the manufacturer. These are less widely accepted due to challenges in quality control, inventory management and logistical coordination. Variability in component quality or specification, or the lack of a reliable supply chain, can lead to inconsistencies, delays and increased risk for the manufacturer. Many prefer sourcing components directly to ensure standardised quality and smoother production.