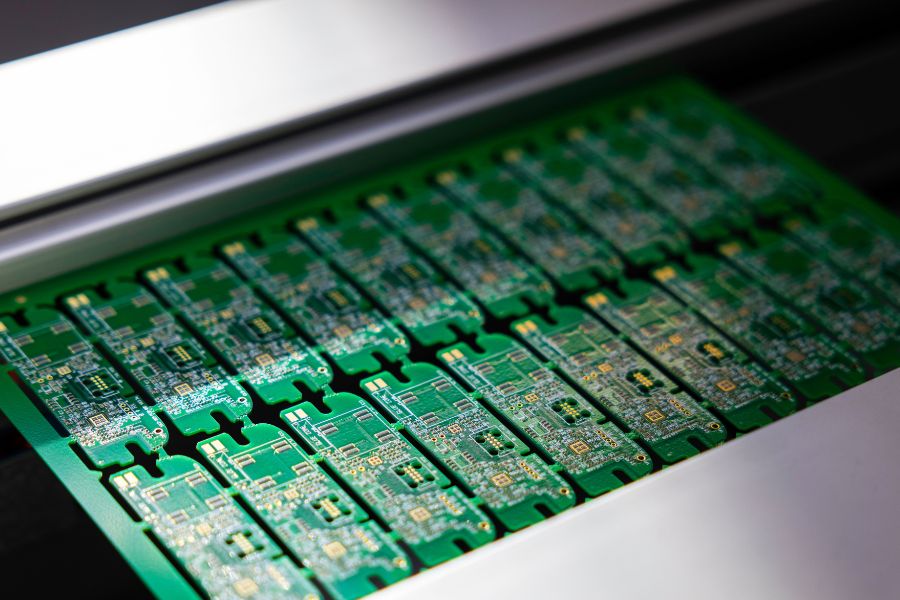

PCB Assembly

Your vision matched with our precision

Your unique electronic product merits a tailored approach. With MPE Electronics you will have a highly skilled, knowledgeable and experienced team assembling and testing PCB assemblies customised to match your exact requirements.

What you can expect from our PCB assembly service

Pre-manufacture

Before commencing production, our engineering team will review all your manufacturing documents to ensure that we have the skills, tools and equipment, and resources to produce your product.

Selecting the PCB assembly method for your product

The choice between Surface Mount Technology (SMT) and Through Hole Technology (THT) depends on the specific requirements of your project, cost considerations, production volume and the nature of the components used. Our team is ready to guide you through the PCB assembly manufacturing process, selecting the most appropriate method for your product.

Surface mount technology

Learn More…

Through Hole Assembly

Learn More…

A trusted supply chain partner

As supply chains around the world become more complex and demand increases, you need a contract electronics manufacturer you can rely on to diligently manage the supply of components and other materials for your PCB assemblies. We do this by providing:

Collaborative strategies to shorten lead times and reduce costs wherever possible

Expertise and experience of supply chain management

Complete transparency into how we work

Accurate forecasting

A focus on quality control

PCB assembly requires precision to guarantee the effectiveness and reliability of your end product, in particular those in critical-to-life applications.

With our highly trained staff and continuous investment in advanced equipment and methodologies, you are guaranteed Class 3 IPC certified printed circuit board assemblies.

Prior to production, the documentation prepared in collaboration with you by our engineering team and specifying how your PCB is to be assembled, is analysed to identify any potential defects or improvements that must be made.

The quality controlled manufacturing process then ensures your PCB assembly is manufactured and tested to meet our superior standards of quality.

With MPE as your contract electronics partner you will be assured of the highest quality PCB assemblies and box builds every time.

Find out more about our quality control standards here.

Continuous improvement in PCB assembly

We capture PCB assembly production data in real time, and along with specified key performance indicators, we identify key trends in production performance. Using these findings, our engineers assess areas for improvement and devise innovative solutions to optimise the critical stages of the printed circuit board assembly manufacturing process.

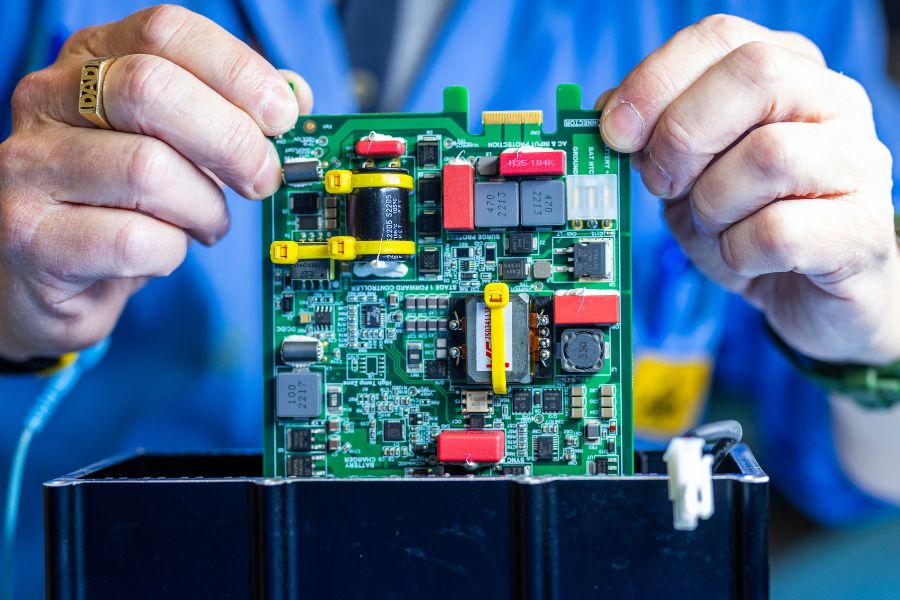

PCB Rework

MPE Electronics carries out PCB rework for commercial and industrial companies and can replace all component types, including BGAs (Ball Grid Arrays) using a PDRX410 Ball Grid Array placement and rework system.

PCB rework can also be completed using the 4 Hakko hot air rework stations in our workshop.

If your business requires a printed circuit board rework, please complete our contact form or contact our sales team on 01825 764822.

Please note that we do not fix or repair PCBs for individual household items.

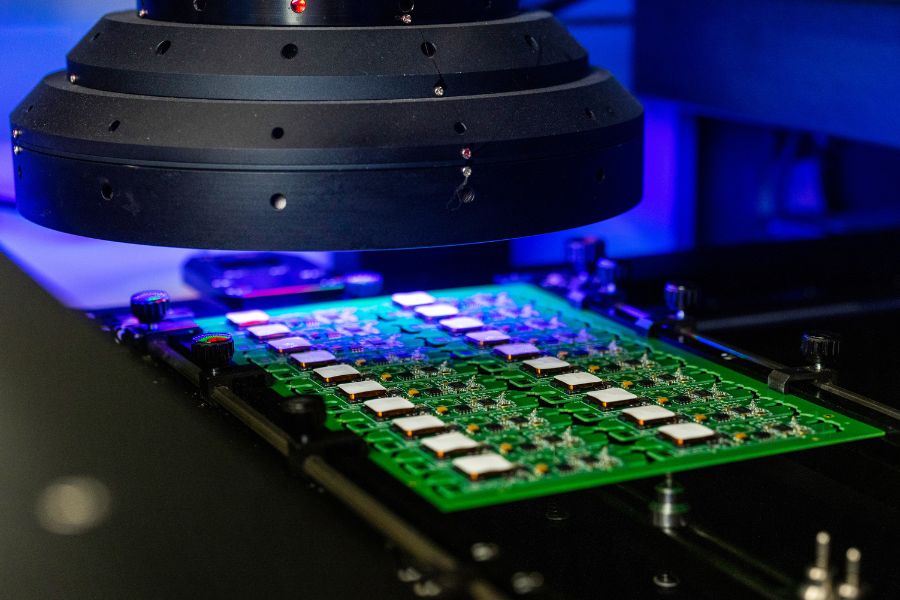

Automated Optical Inspection

We commit to AOI 100% of every build after SMT.

Box Build Assembly

Optimise your supply chain with our turnkey assembly service.