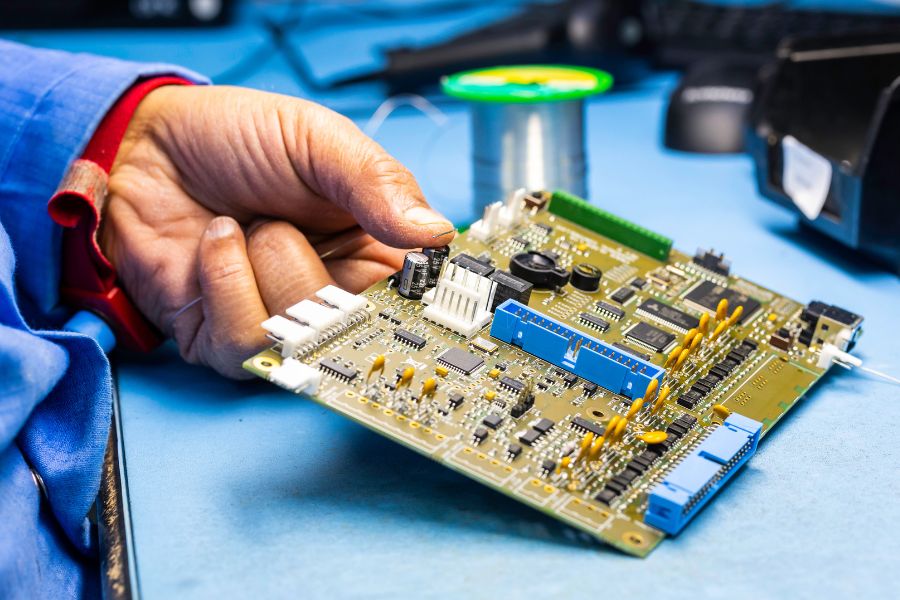

PCB design

Detailed PCB design

A well-executed PCB design ensures optimal performance of your electronic product, facilitates efficient manufacturing and supports compliance with industry standards and regulations.

MPE collaborates closely with specialised and well-established local partners, who bring a wealth of experience and expertise to the process of designing your PCB. Through this collaboration, we ensure that your PCBs are meticulously crafted, meeting the highest standards of quality and functionality.

Contact our specialist team to discuss your PCB assembly & Box Build requirements

What you can expect from our PCB design process

Before we connect with our design partners, we define your PCB design requirements by posing the following questions to you and your team:

What is the desired application for your PCB assembly?

What size of PCBA is required?

Is the PCBA intended to be connected to other parts of an embedded system?

What kind of environmental conditions will the PCB assembly be exposed to?

Next, we coordinate with our design partners to follow the defined steps of our design process:

Creating a Schematic

Once requirements are established, the designer will proceed to create a schematic diagram, encompassing the details of the PCB design. It will specify the components required, their positioning and interconnection. Additionally, the costing of materials, coupled with an assessment of their availability in the supply chain, will be comprehensively addressed during this stage.

Electronic PCB Design Automation Software

The intricacies specified in the schematic are diligently input into an electronic design automation software package. This sophisticated software then generates and compiles a comprehensive set of documents, commonly known as a Gerber or Computer-Aided Design (CAD) file. This carefully generated file serves as the definitive set of instructions for manufacturing your PCB assembly.

Select the Manufacturing Method

The choice of manufacturing method is contingent upon the initial requirements defined within the schematic, along with considerations for available materials, resources, project timelines, and production budget constraints.

Testing

Integral to the design process is the specification of the requisite tests required to verify your PCBA meets your desired design requirements. Employing a variety of testing techniques, we ensure that your PCB assembly will meet the performance standards expected.

Next stages of your product development journey

Clear and prompt communications

Our team takes control of all communication with our design partner, aiming for efficient issue resolution and maintaining accountability to ensure a consistent and clear messaging approach. Through this proactive management, MPE guarantees that our partner’s actions and objectives closely align with the overarching strategic goals of your PCB design project.

PCB prototyping and manufacture

Our New Product Introduction (NPI) procedure outlines the stages that follow on from the design of your PCB:

Product design

Primary prototyping

Product development

Secondary prototyping

Full manufacturing

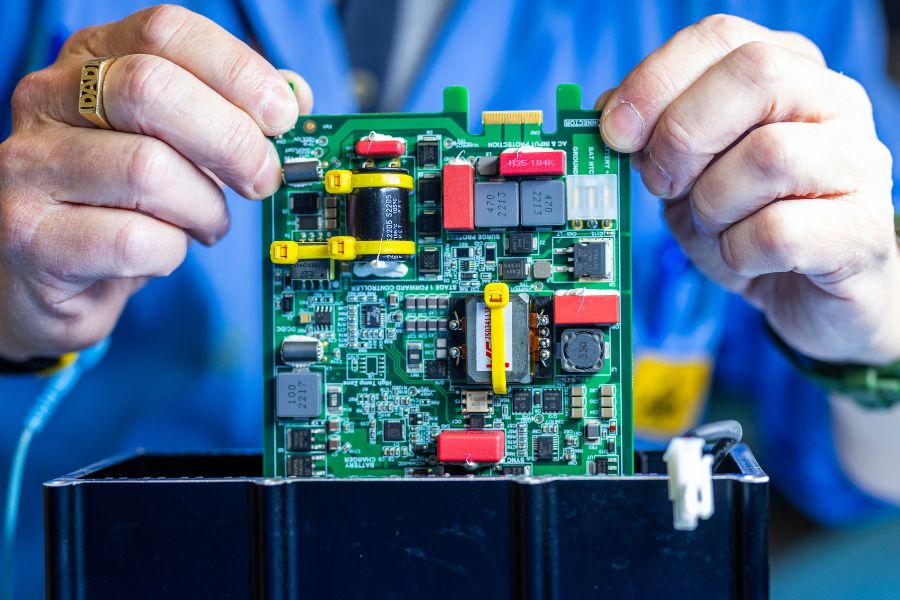

PCB Assembly

Precise, reliable PCB assembly to your exact requirements.

Box Build Assembly

Optimise your supply chain with our turnkey assembly service.